Konstantinos Dermitzakis

Bio-inspired friction switches: adaptive pulley systems

Jan 21, 2014

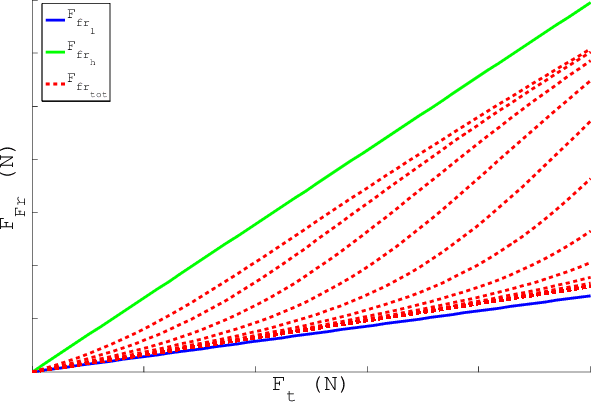

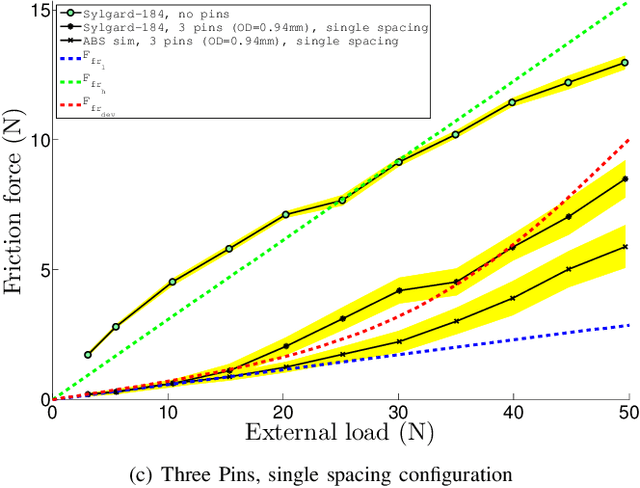

Abstract:Frictional influences in tendon-driven robotic systems are generally unwanted, with efforts towards minimizing them where possible. In the human hand however, the tendon-pulley system is found to be frictional with a difference between high-loaded static post-eccentric and post-concentric force production of 9-12% of the total output force. This difference can be directly attributed to tendon-pulley friction. Exploiting this phenomenon for robotic and prosthetic applications we can achieve a reduction of actuator size, weight and consequently energy consumption. In this study, we present the design of a bio-inspired friction switch. The adaptive pulley is designed to minimize the influence of frictional forces under low and medium-loading conditions and maximize it under high-loading conditions. This is achieved with a dual-material system that consists of a high-friction silicone substrate and low-friction polished steel pins. The system, designed to switch its frictional properties between the low-loaded and high-loaded conditions, is described and its behavior experimentally validated with respect to the number and spacing of pins. The results validate its intended behavior, making it a viable choice for robotic tendon-driven systems.

* Conference. First submission, before reviews

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge