Ken Bruton

Development and application of a machine learning supported methodology for measurement and verification (M&V) 2.0

Jan 24, 2018

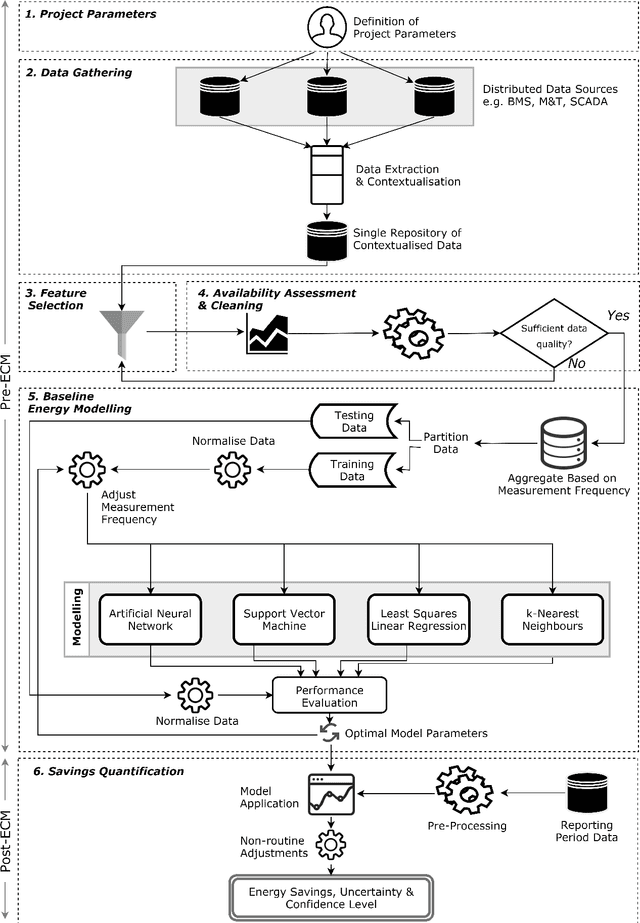

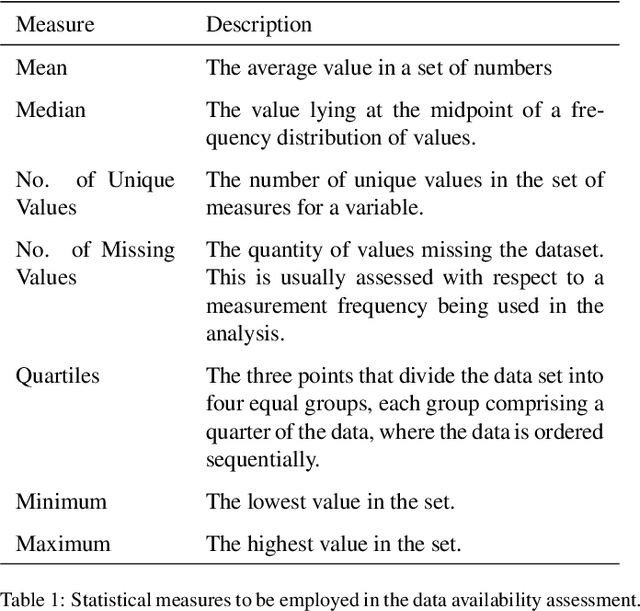

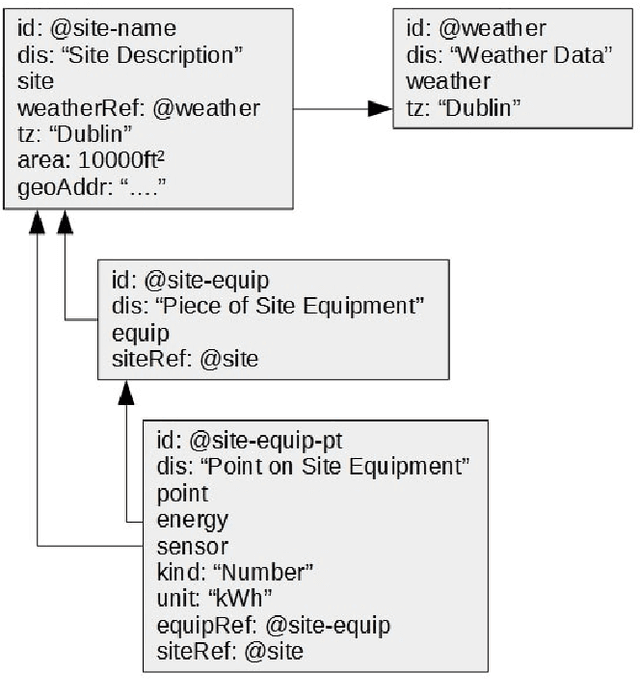

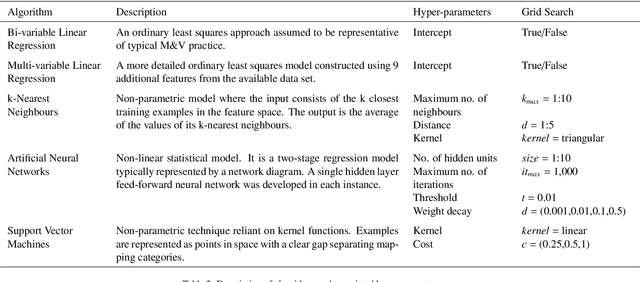

Abstract:The foundations of all methodologies for the measurement and verification (M&V) of energy savings are based on the same five key principles: accuracy, completeness, conservatism, consistency and transparency. The most widely accepted methodologies tend to generalise M&V so as to ensure applicability across the spectrum of energy conservation measures (ECM's). These do not provide a rigid calculation procedure to follow. This paper aims to bridge the gap between high-level methodologies and the practical application of modelling algorithms, with a focus on the industrial buildings sector. This is achieved with the development of a novel, machine learning supported methodology for M&V 2.0 which enables accurate quantification of savings. A novel and computationally efficient feature selection algorithm and powerful machine learning regression algorithms are employed to maximise the effectiveness of available data. The baseline period energy consumption is modelled using artificial neural networks, support vector machines, k-nearest neighbours and multiple ordinary least squares regression. Improved knowledge discovery and an expanded boundary of analysis allow more complex energy systems be analysed, thus increasing the applicability of M&V. A case study in a large biomedical manufacturing facility is used to demonstrate the methodology's ability to accurately quantify the savings under real-world conditions. The ECM was found to result in 604,527 kWh of energy savings with 57% uncertainty at a confidence interval of 68%. 20 baseline energy models are developed using an exhaustive approach with the optimal model being used to quantify savings. The range of savings estimated with each model are presented and the acceptability of uncertainty is reviewed. The case study demonstrates the ability of the methodology to perform M&V to an acceptable standard in challenging circumstances.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge