Karthik Urs

The Robot of Theseus: A modular robotic testbed for legged locomotion

May 19, 2025Abstract:Robotic models are useful for independently varying specific features, but most quadrupedal robots differ so greatly from animal morphologies that they have minimal biomechanical relevance. Commercially available quadrupedal robots are also prohibitively expensive for biological research programs and difficult to customize. Here, we present a low-cost quadrupedal robot with modular legs that can match a wide range of animal morphologies for biomechanical hypothesis testing. The Robot Of Theseus (TROT) costs approximately $4000 to build out of 3D printed parts and standard off-the-shelf supplies. Each limb consists of 2 or 3 rigid links; the proximal joint can be rotated to become a knee or elbow. Telescoping mechanisms vary the length of each limb link. The open-source software accommodates user-defined gaits and morphology changes. Effective leg length, or crouch, is determined by the four-bar linkage actuating each joint. The backdrivable motors can vary virtual spring stiffness and range of motion. Full descriptions of the TROT hardware and software are freely available online. We demonstrate the use of TROT to compare locomotion among extant, extinct, and theoretical morphologies. In addition to biomechanical hypothesis testing, we envision a variety of different applications for this low-cost, modular, legged robotic platform, including developing novel control strategies, clearing land mines, or remote exploration. All CAD and code is available for download on the TROT project page.

Design and Characterization of 3D Printed, Open-Source Actuators for Legged Locomotion

Feb 24, 2022

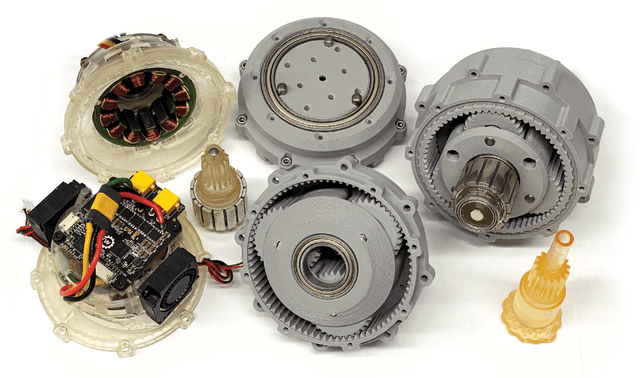

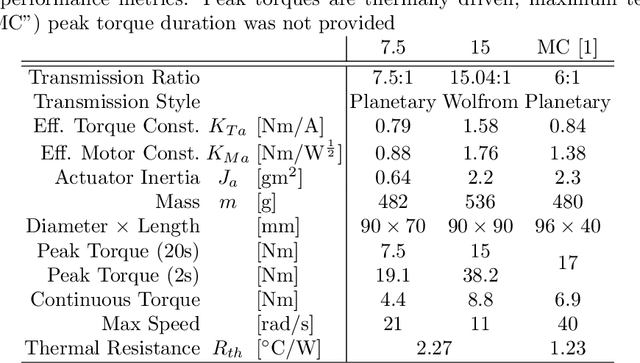

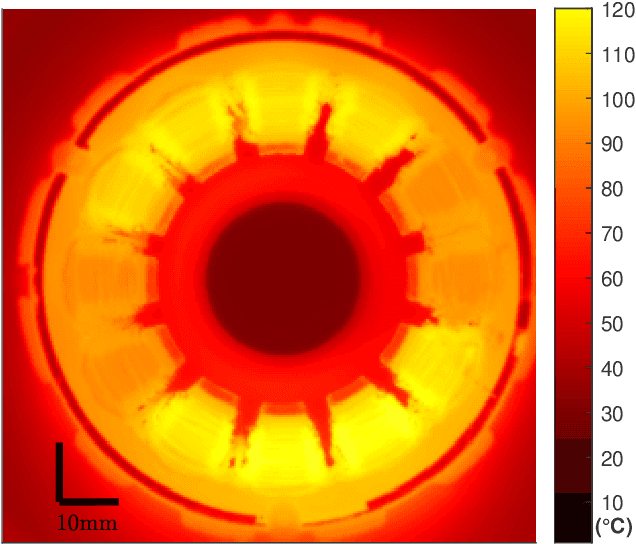

Abstract:Impressive animal locomotion capabilities are mediated by the co-evolution of the skeletal morphology and muscular properties. Legged robot performance would also likely benefit from the co-optimization of actuators and leg morphology. However, development of custom actuators for legged robots is often expensive and time consuming, which discourages roboticists from pursuing performance gains afforded by application-specific actuator optimization. This paper presents open-source designs for two quasi-direct-drive actuators with performance regimes appropriate for an 8--15 kg robot, built completely with off the shelf and 3D-printed components for less than $200 USD each. The mechanical, electrical, and thermal properties of each actuator are characterized and compared to benchmark data. Actuators subjected to 420k strides of gait data experienced only a 2% reduction in efficiency and 26 mrad in backlash growth, demonstrating viability for rigorous and sustained research applications. We present a thermal solution that nearly doubles the thermally-driven torque limits of our plastic actuator design. The performance results are comparable to traditional metallic actuators for use in high-speed legged robots of the same scale. These 3D printed designs demonstrate an approach for designing and characterizing low-cost, highly customizable, and highly reproducible actuators, democratizing the field of actuator design and enabling co-design and optimization of actuators and robot legs.

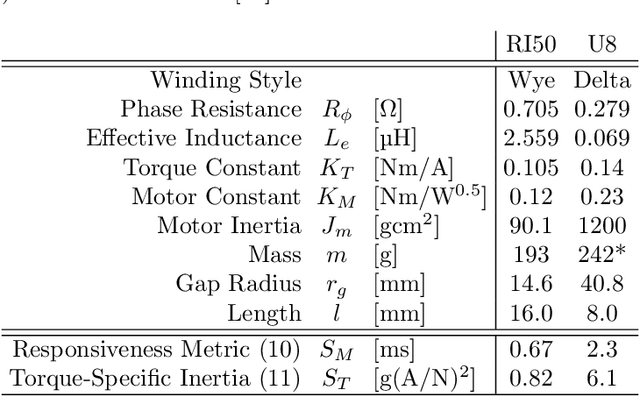

Alternative Metrics to Select Motors for Quasi-Direct Drive Actuators

Feb 24, 2022

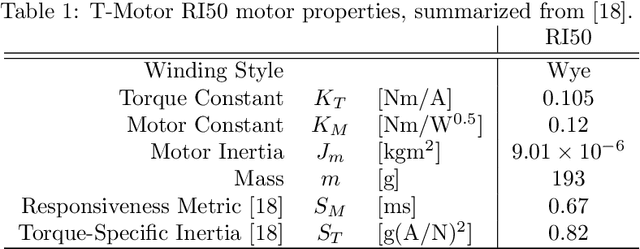

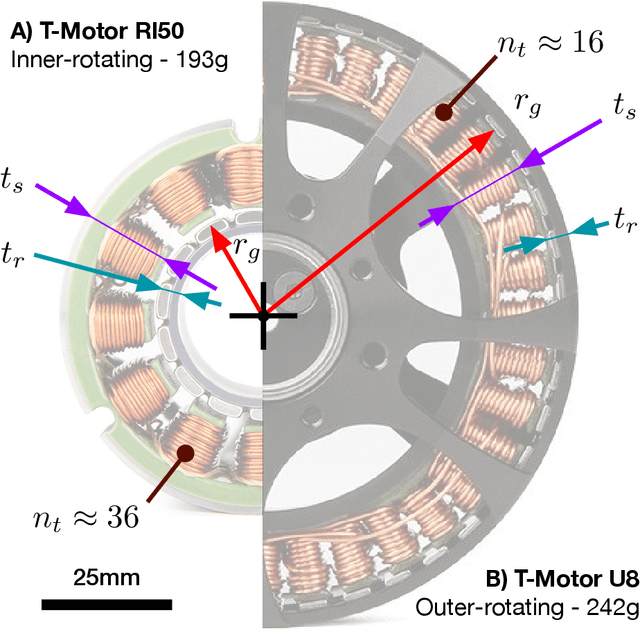

Abstract:Robotic systems for legged locomotion -- including legged robots, exoskeletons, and prosthetics -- require actuators with low inertia and high output torque. Traditionally, motors have been selected for these applications by maximizing the motor gap radius. We present alternative metrics for motor selection that are invariant to transmission ratio. The proposed metrics reward minimizing the motor inertia while maximizing the torque and motor constants without special consideration for gap radius, providing a better balance of properties for legged locomotion applications. We rigorously characterize the T-Motor RI50 and demonstrate the use of the metrics by comparing the RI50 to the widely-used T-Motor U8 as a case study.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge