Jyun-Ming Liao

Physics-data hybrid dynamic model of a multi-axis manipulator for sensorless dexterous manipulation and high-performance motion planning

May 07, 2024

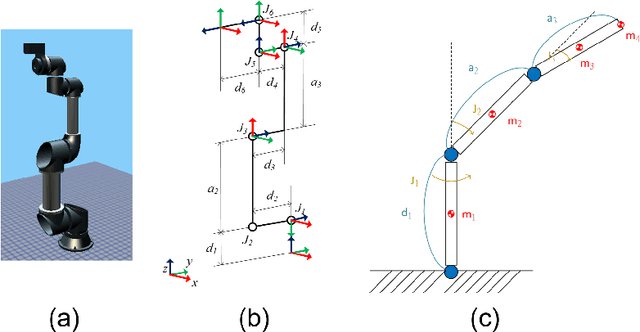

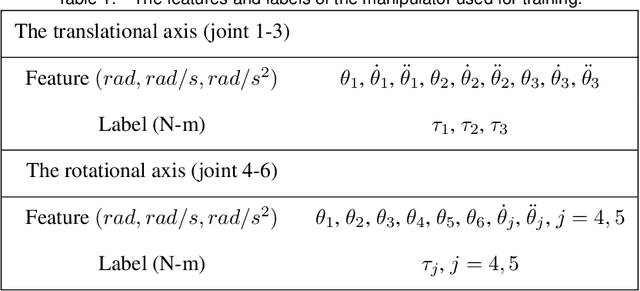

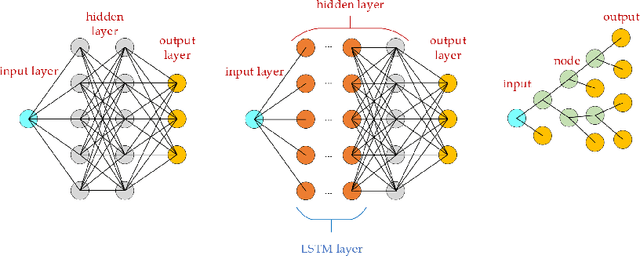

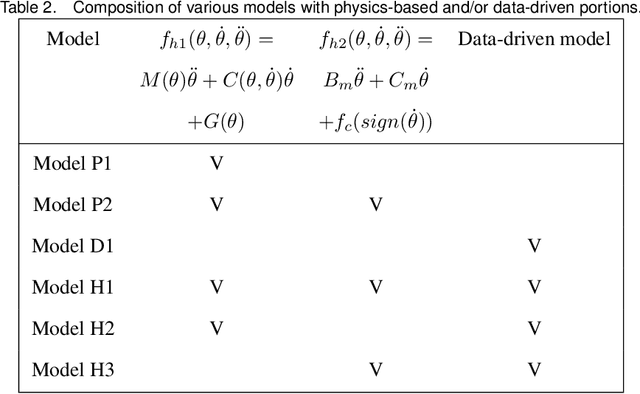

Abstract:We report on the development of an implementable physics-data hybrid dynamic model for an articulated manipulator to plan and operate in various scenarios. Meanwhile, the physics-based and data-driven dynamic models are studied in this research to select the best model for planning. The physics-based model is constructed using the Lagrangian method, and the loss terms include inertia loss, viscous loss, and friction loss. As for the data-driven model, three methods are explored, including DNN, LSTM, and XGBoost. Our modeling results demonstrate that, after comprehensive hyperparameter optimization, the XGBoost architecture outperforms DNN and LSTM in accurately representing manipulator dynamics. The hybrid model with physics-based and data-driven terms has the best performance among all models based on the RMSE criteria, and it only needs about 24k of training data. In addition, we developed a virtual force sensor of a manipulator using the observed external torque derived from the dynamic model and designed a motion planner through the physics-data hybrid dynamic model. The external torque contributes to forces and torque on the end effector, facilitating interaction with the surroundings, while the internal torque governs manipulator motion dynamics and compensates for internal losses. By estimating external torque via the difference between measured joint torque and internal losses, we implement a sensorless control strategy which is demonstrated through a peg-in-hole task. Lastly, a learning-based motion planner based on the hybrid dynamic model assists in planning time-efficient trajectories for the manipulator. This comprehensive approach underscores the efficacy of integrating physics-based and data-driven models for advanced manipulator control and planning in industrial environments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge