Julia B. Nakhleh

Identifying Entangled Physics Relationships through Sparse Matrix Decomposition to Inform Plasma Fusion Design

Oct 28, 2020

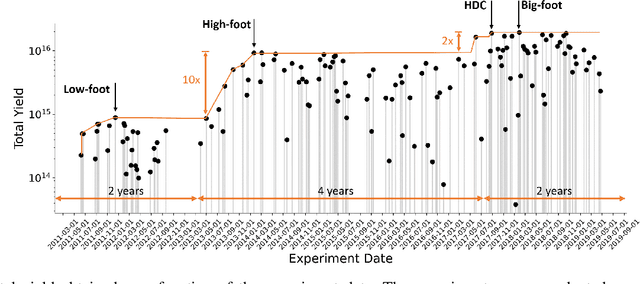

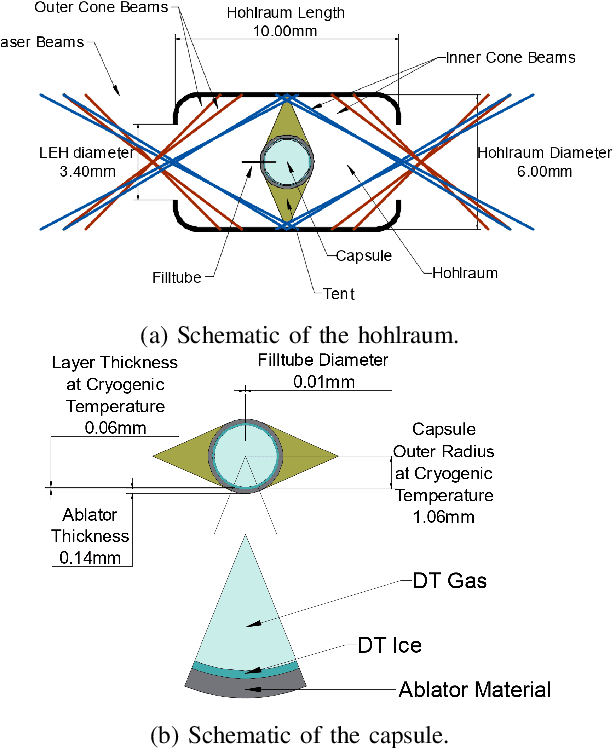

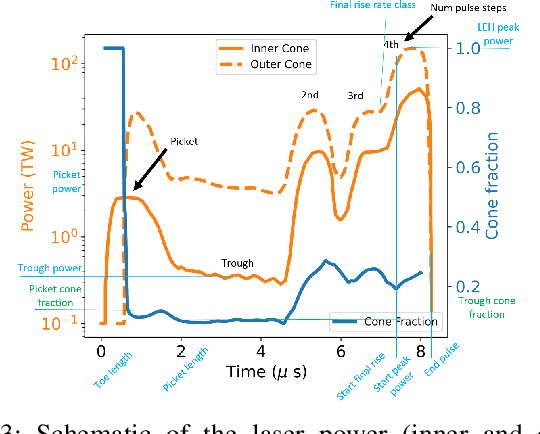

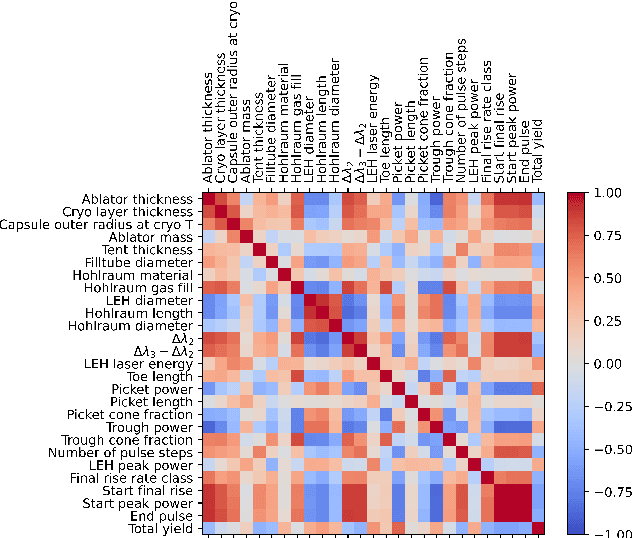

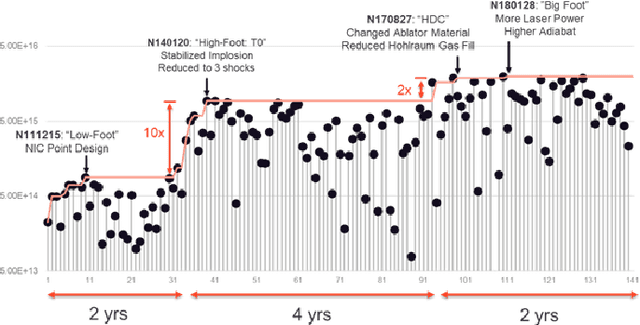

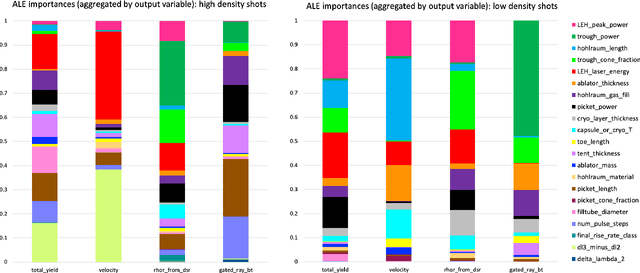

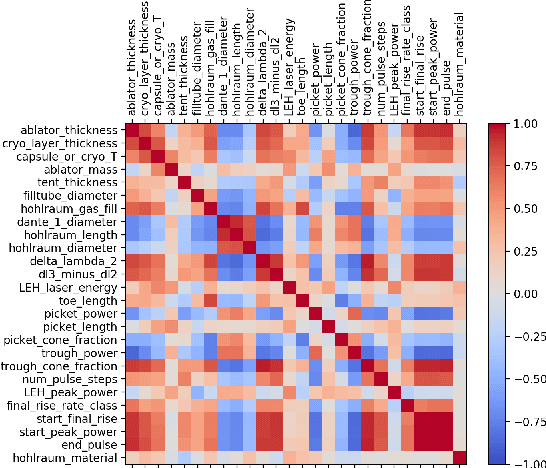

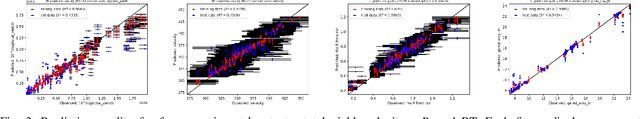

Abstract:A sustainable burn platform through inertial confinement fusion (ICF) has been an ongoing challenge for over 50 years. Mitigating engineering limitations and improving the current design involves an understanding of the complex coupling of physical processes. While sophisticated simulations codes are used to model ICF implosions, these tools contain necessary numerical approximation but miss physical processes that limit predictive capability. Identification of relationships between controllable design inputs to ICF experiments and measurable outcomes (e.g. yield, shape) from performed experiments can help guide the future design of experiments and development of simulation codes, to potentially improve the accuracy of the computational models used to simulate ICF experiments. We use sparse matrix decomposition methods to identify clusters of a few related design variables. Sparse principal component analysis (SPCA) identifies groupings that are related to the physical origin of the variables (laser, hohlraum, and capsule). A variable importance analysis finds that in addition to variables highly correlated with neutron yield such as picket power and laser energy, variables that represent a dramatic change of the ICF design such as number of pulse steps are also very important. The obtained sparse components are then used to train a random forest (RF) surrogate for predicting total yield. The RF performance on the training and testing data compares with the performance of the RF surrogate trained using all design variables considered. This work is intended to inform design changes in future ICF experiments by augmenting the expert intuition and simulations results.

Exploring Sensitivity of ICF Outputs to Design Parameters in Experiments Using Machine Learning

Oct 08, 2020

Abstract:Building a sustainable burn platform in inertial confinement fusion (ICF) requires an understanding of the complex coupling of physical processes and the effects that key experimental design changes have on implosion performance. While simulation codes are used to model ICF implosions, incomplete physics and the need for approximations deteriorate their predictive capability. Identification of relationships between controllable design inputs and measurable outcomes can help guide the future design of experiments and development of simulation codes, which can potentially improve the accuracy of the computational models used to simulate ICF implosions. In this paper, we leverage developments in machine learning (ML) and methods for ML feature importance/sensitivity analysis to identify complex relationships in ways that are difficult to process using expert judgment alone. We present work using random forest (RF) regression for prediction of yield, velocity, and other experimental outcomes given a suite of design parameters, along with an assessment of important relationships and uncertainties in the prediction model. We show that RF models are capable of learning and predicting on ICF experimental data with high accuracy, and we extract feature importance metrics that provide insight into the physical significance of different controllable design inputs for various ICF design configurations. These results can be used to augment expert intuition and simulation results for optimal design of future ICF experiments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge