Jason C. Jones

Automated Copper Alloy Grain Size Evaluation Using a Deep-learning CNN

May 20, 2020

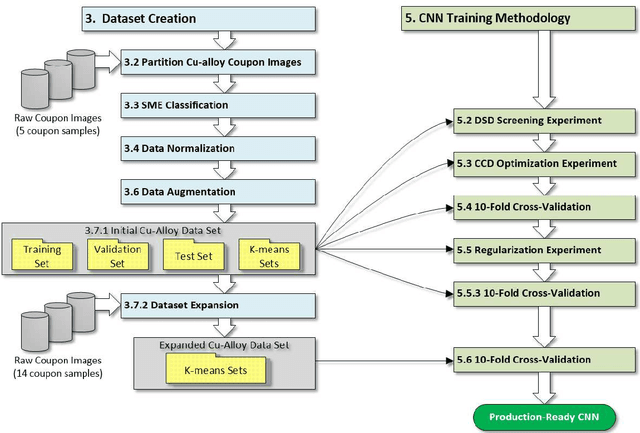

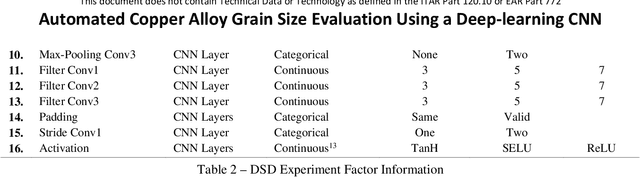

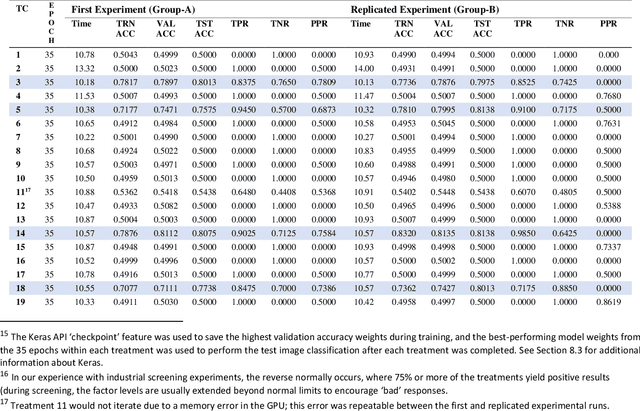

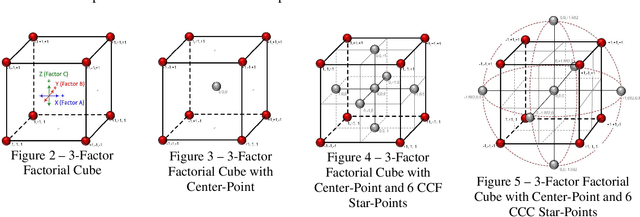

Abstract:Moog Inc. has automated the evaluation of copper (Cu) alloy grain size using a deep-learning convolutional neural network (CNN). The proof-of-concept automated image acquisition and batch-wise image processing offers the potential for significantly reduced labor, improved accuracy of grain evaluation, and decreased overall turnaround times for approving Cu alloy bar stock for use in flight critical aircraft hardware. A classification accuracy of 91.1% on individual sub-images of the Cu alloy coupons was achieved. Process development included minimizing the variation in acquired image color, brightness, and resolution to create a dataset with 12300 sub-images, and then optimizing the CNN hyperparameters on this dataset using statistical design of experiments (DoE). Over the development of the automated Cu alloy grain size evaluation, a degree of "explainability" in the artificial intelligence (XAI) output was realized, based on the decomposition of the large raw images into many smaller dataset sub-images, through the ability to explain the CNN ensemble image output via inspection of the classification results from the individual smaller sub-images.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge