Jamie Hathaway

End-to-end example-based sim-to-real RL policy transfer based on neural stylisation with application to robotic cutting

Jan 28, 2026Abstract:Whereas reinforcement learning has been applied with success to a range of robotic control problems in complex, uncertain environments, reliance on extensive data - typically sourced from simulation environments - limits real-world deployment due to the domain gap between simulated and physical systems, coupled with limited real-world sample availability. We propose a novel method for sim-to-real transfer of reinforcement learning policies, based on a reinterpretation of neural style transfer from image processing to synthesise novel training data from unpaired unlabelled real world datasets. We employ a variational autoencoder to jointly learn self-supervised feature representations for style transfer and generate weakly paired source-target trajectories to improve physical realism of synthesised trajectories. We demonstrate the application of our approach based on the case study of robot cutting of unknown materials. Compared to baseline methods, including our previous work, CycleGAN, and conditional variational autoencoder-based time series translation, our approach achieves improved task completion time and behavioural stability with minimal real-world data. Our framework demonstrates robustness to geometric and material variation, and highlights the feasibility of policy adaptation in challenging contact-rich tasks where real-world reward information is unavailable.

Imitation learning for sim-to-real transfer of robotic cutting policies based on residual Gaussian process disturbance force model

Nov 07, 2023

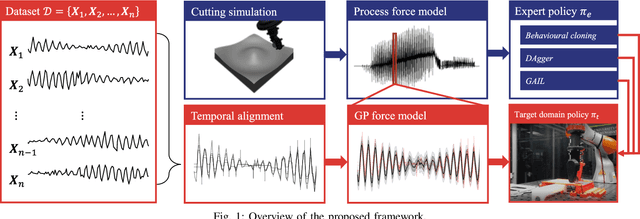

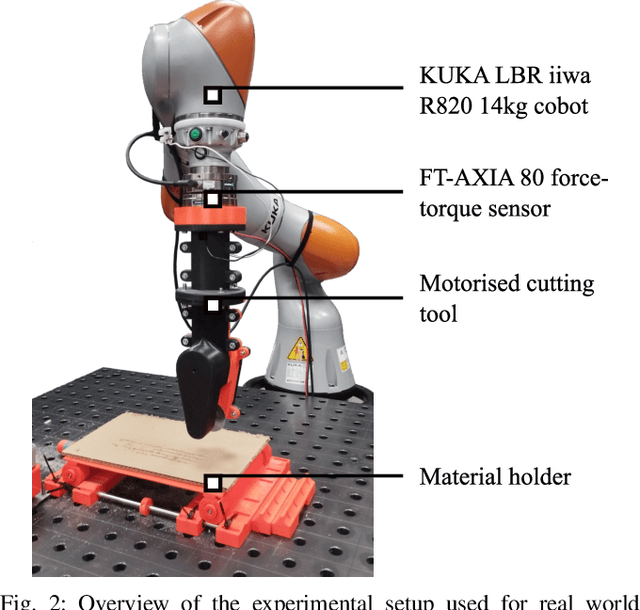

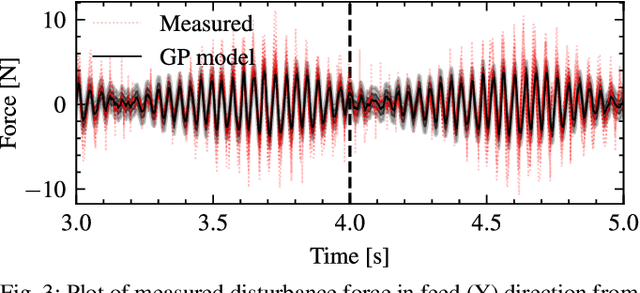

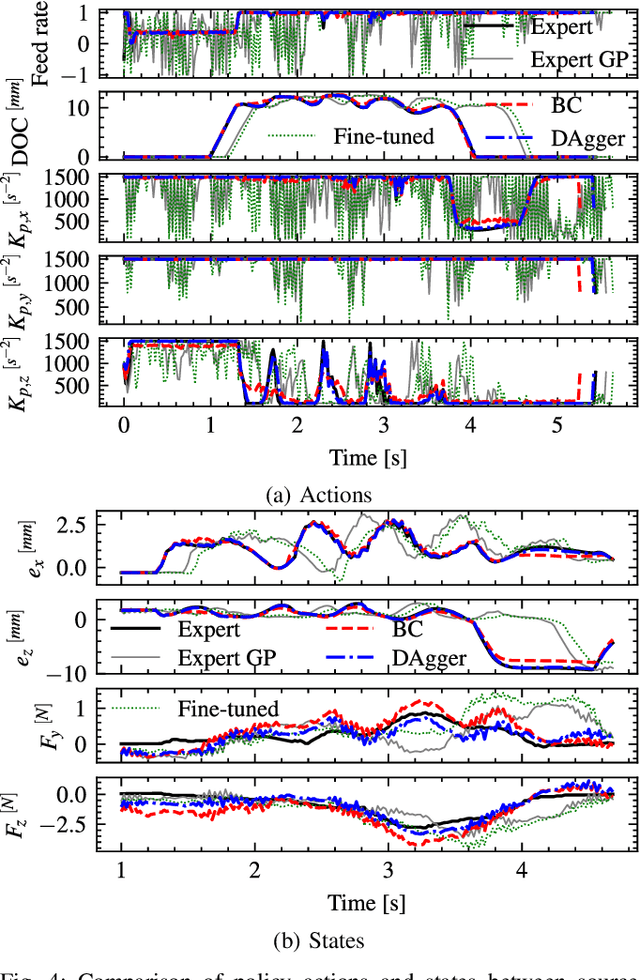

Abstract:Robotic cutting, or milling, plays a significant role in applications such as disassembly, decommissioning, and demolition. Planning and control of cutting in real-world scenarios in uncertain environments is a complex task, with the potential to benefit from simulated training environments. This letter focuses on sim-to-real transfer for robotic cutting policies, addressing the need for effective policy transfer from simulation to practical implementation. We extend our previous domain generalisation approach to learning cutting tasks based on a mechanistic model-based simulation framework, by proposing a hybrid approach for sim-to-real transfer based on a milling process force model and residual Gaussian process (GP) force model, learned from either single or multiple real-world cutting force examples. We demonstrate successful sim-to-real transfer of a robotic cutting policy without the need for fine-tuning on the real robot setup. The proposed approach autonomously adapts to materials with differing structural and mechanical properties. Furthermore, we demonstrate the proposed method outperforms fine-tuning or re-training alone.

Towards Reuse and Recycling of Lithium-ion Batteries: Tele-robotics for Disassembly of Electric Vehicle Batteries

Apr 03, 2023

Abstract:Disassembly of electric vehicle batteries is a critical stage in recovery, recycling and re-use of high-value battery materials, but is complicated by limited standardisation, design complexity, compounded by uncertainty and safety issues from varying end-of-life condition. Telerobotics presents an avenue for semi-autonomous robotic disassembly that addresses these challenges. However, it is suggested that quality and realism of the user's haptic interactions with the environment is important for precise, contact-rich and safety-critical tasks. To investigate this proposition, we demonstrate the disassembly of a Nissan Leaf 2011 module stack as a basis for a comparative study between a traditional asymmetric haptic-'cobot' master-slave framework and identical master and slave cobots based on task completion time and success rate metrics. We demonstrate across a range of disassembly tasks a time reduction of 22%-57% is achieved using identical cobots, yet this improvement arises chiefly from an expanded workspace and 1:1 positional mapping, and suffers a 10-30% reduction in first attempt success rate. For unbolting and grasping, the realism of force feedback was comparatively less important than directional information encoded in the interaction, however, 1:1 force mapping strengthened environmental tactile cues for vacuum pick-and-place and contact cutting tasks.

Learning robotic milling strategies based on passive variable operational space interaction control

Apr 03, 2023Abstract:This paper addresses the problem of robotic cutting during disassembly of products for materials separation and recycling. Waste handling applications differ from milling in manufacturing processes, as they engender considerable variety and uncertainty in the parameters (e.g. hardness) of materials which the robot must cut. To address this challenge, we propose a learning-based approach incorporating elements of interaction control, in which the robot can adapt key parameters, such as feed rate, depth of cut, and mechanical compliance during task execution. We show how a mathematical model of cutting mechanics, embedded in a simulation environment, can be used to rapidly train the system without needing large amounts of data from physical cutting trials. The simulation approach was validated on a real robot setup based on four case study materials with varying structural and mechanical properties. We demonstrate the proposed method minimises process force and path deviations to a level similar to offline optimal planning methods, while the average time to complete a cutting task is within 25% of the optimum, at the expense of reduced volume of material removed per pass. A key advantage of our approach over similar works is that no prior knowledge about the material is required.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge