Jürg Schiffmann

DATED: Guidelines for Creating Synthetic Datasets for Engineering Design Applications

May 15, 2023

Abstract:Exploiting the recent advancements in artificial intelligence, showcased by ChatGPT and DALL-E, in real-world applications necessitates vast, domain-specific, and publicly accessible datasets. Unfortunately, the scarcity of such datasets poses a significant challenge for researchers aiming to apply these breakthroughs in engineering design. Synthetic datasets emerge as a viable alternative. However, practitioners are often uncertain about generating high-quality datasets that accurately represent real-world data and are suitable for the intended downstream applications. This study aims to fill this knowledge gap by proposing comprehensive guidelines for generating, annotating, and validating synthetic datasets. The trade-offs and methods associated with each of these aspects are elaborated upon. Further, the practical implications of these guidelines are illustrated through the creation of a turbo-compressors dataset. The study underscores the importance of thoughtful sampling methods to ensure the appropriate size, diversity, utility, and realism of a dataset. It also highlights that design diversity does not equate to performance diversity or realism. By employing test sets that represent uniform, real, or task-specific samples, the influence of sample size and sampling strategy is scrutinized. Overall, this paper offers valuable insights for researchers intending to create and publish synthetic datasets for engineering design, thereby paving the way for more effective applications of AI advancements in the field. The code and data for the dataset and methods are made publicly accessible at https://github.com/cyrilpic/radcomp .

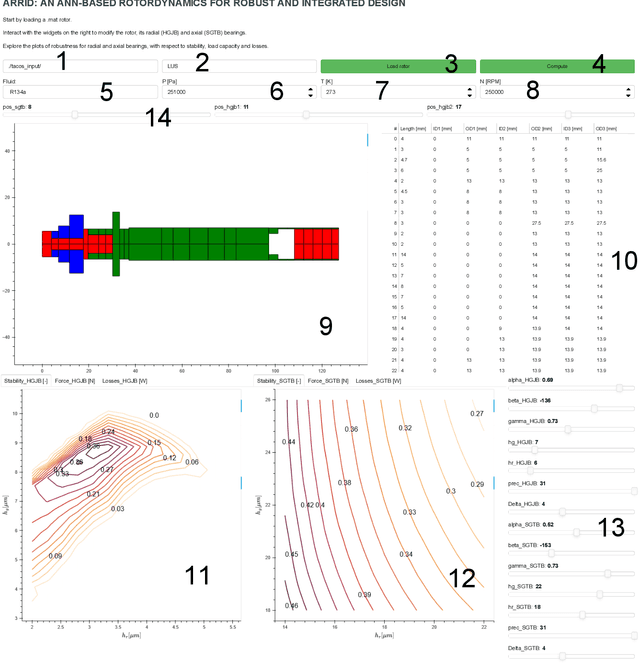

ARRID: ANN-based Rotordynamics for Robust and Integrated Design

Aug 25, 2022

Abstract:The purpose of this study is to introduce ANN-based software for the fast evaluation of rotordynamics in the context of robust and integrated design. It is based on a surrogate model made of ensembles of artificial neural networks running in a Bokeh web application. The use of a surrogate model has sped up the computation by three orders of magnitude compared to the current models. ARRID offers fast performance information, including the effect of manufacturing deviations. As such, it helps the designer to make optimal design choices early in the design process. The designer can manipulate the parameters of the design and the operating conditions to obtain performance information in a matter of seconds.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge