Elmar Wolfgang Lang

Playing Ping Pong with Light: Directional Emission of White Light

Nov 30, 2021

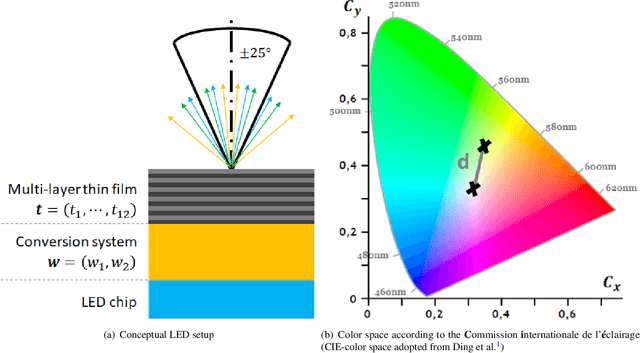

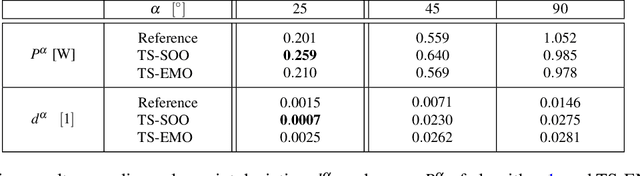

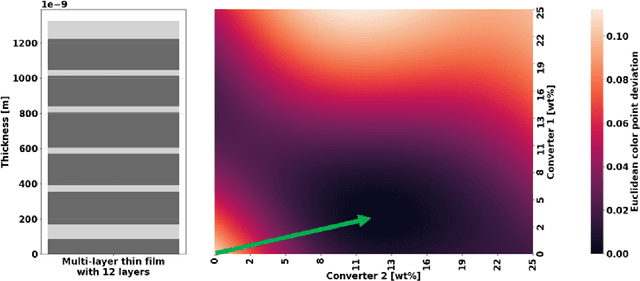

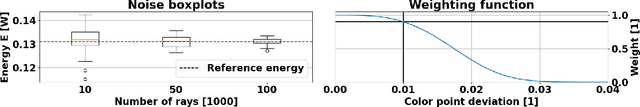

Abstract:Over the last decades, light-emitting diodes (LED) have replaced common light bulbs in almost every application, from flashlights in smartphones to automotive headlights. Illuminating nightly streets requires LEDs to emit a light spectrum that is perceived as pure white by the human eye. The power associated with such a white light spectrum is not only distributed over the contributing wavelengths but also over the angles of vision. For many applications, the usable light rays are required to exit the LED in forward direction, namely under small angles to the perpendicular. In this work, we demonstrate that a specifically designed multi-layer thin film on top of a white LED increases the power of pure white light emitted in forward direction. Therefore, the deduced multi-objective optimization problem is reformulated via a real-valued physics-guided objective function that represents the hierarchical structure of our engineering problem. Variants of Bayesian optimization are employed to maximize this non-deterministic objective function based on ray tracing simulations. Eventually, the investigation of optical properties of suitable multi-layer thin films allowed to identify the mechanism behind the increased directionality of white light: angle and wavelength selective filtering causes the multi-layer thin film to play ping pong with rays of light.

Decomposing Temperature Time Series with Non-Negative Matrix Factorization

Apr 03, 2019

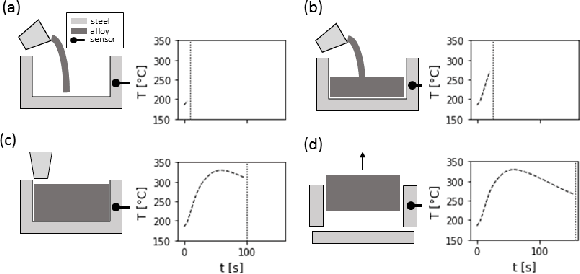

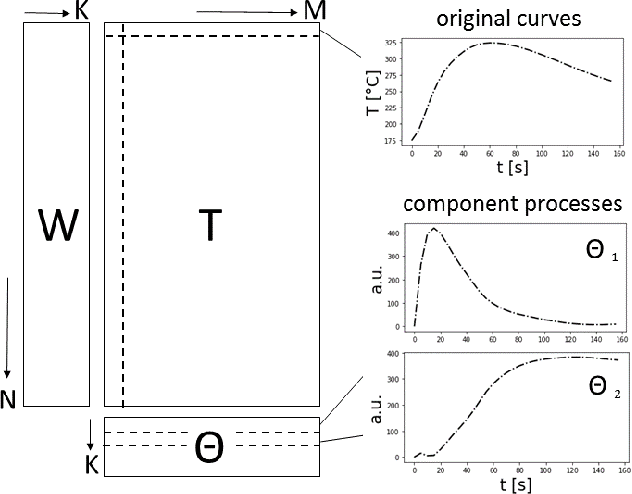

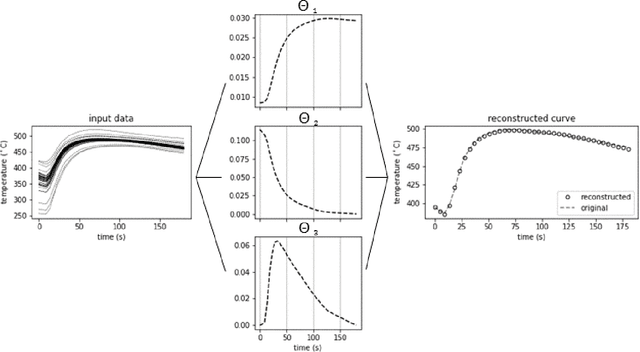

Abstract:During the fabrication of casting parts sensor data is typically automatically recorded and accumulated for process monitoring and defect diagnosis. As casting is a thermal process with many interacting process parameters, root cause analysis tends to be tedious and ineffective. We show how a decomposition based on non-negative matrix factorization (NMF), which is guided by a knowledge-based initialization strategy, is able to extract physical meaningful sources from temperature time series collected during a thermal manufacturing process. The approach assumes the time series to be generated by a superposition of several simultaneously acting component processes. NMF is able to reverse the superposition and to identify the hidden component processes. The latter can be linked to ongoing physical phenomena and process variables, which cannot be monitored directly. Our approach provides new insights into the underlying physics and offers a tool, which can assist in diagnosing defect causes. We demonstrate our method by applying it to real world data, collected in a foundry during the series production of casting parts for the automobile industry.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge