Dominik Flore

Deep learning based Meta-modeling for Multi-objective Technology Optimization of Electrical Machines

Jun 15, 2023

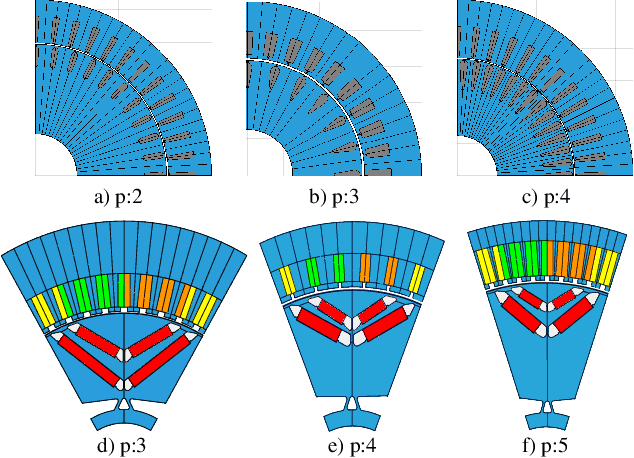

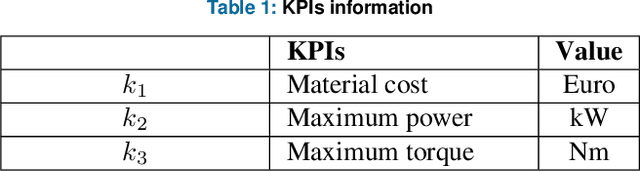

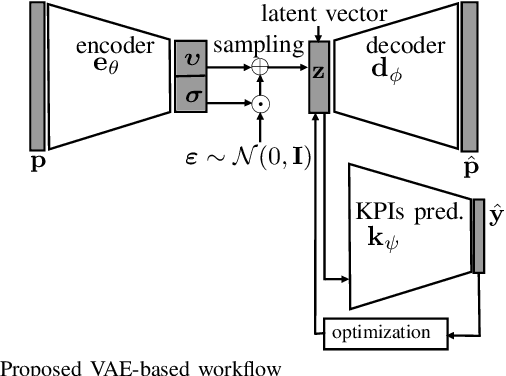

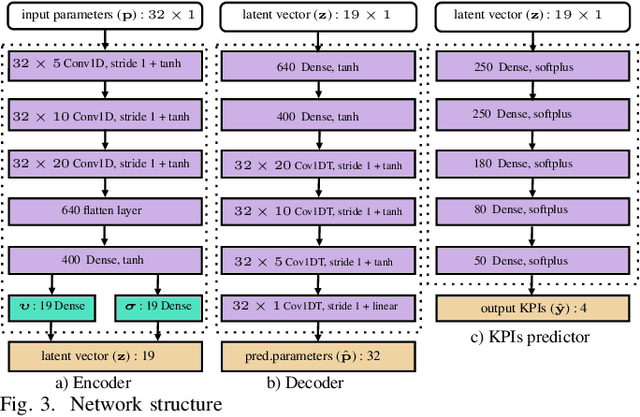

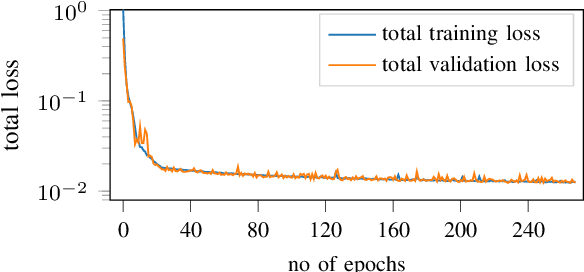

Abstract:Optimization of rotating electrical machines is both time- and computationally expensive. Because of the different parametrization, design optimization is commonly executed separately for each machine technology. In this paper, we present the application of a variational auto-encoder (VAE) to optimize two different machine technologies simultaneously, namely an asynchronous machine and a permanent magnet synchronous machine. After training, we employ a deep neural network and a decoder as meta-models to predict global key performance indicators (KPIs) and generate associated new designs, respectively, through unified latent space in the optimization loop. Numerical results demonstrate concurrent parametric multi-objective technology optimization in the high-dimensional design space. The VAE-based approach is quantitatively compared to a classical deep learning-based direct approach for KPIs prediction.

Multi-Objective Optimization of Electrical Machines using a Hybrid Data-and Physics-Driven Approach

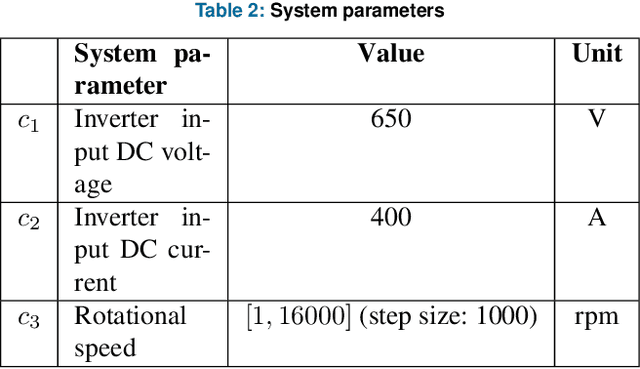

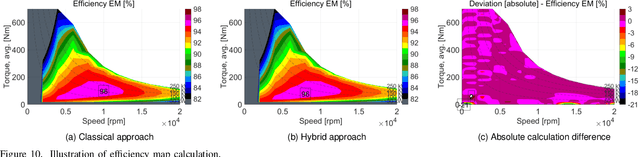

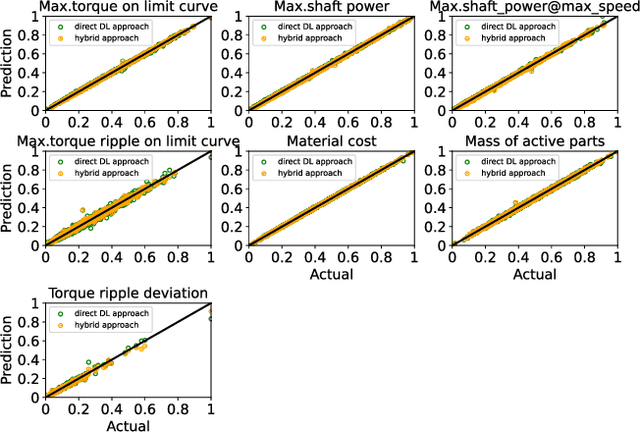

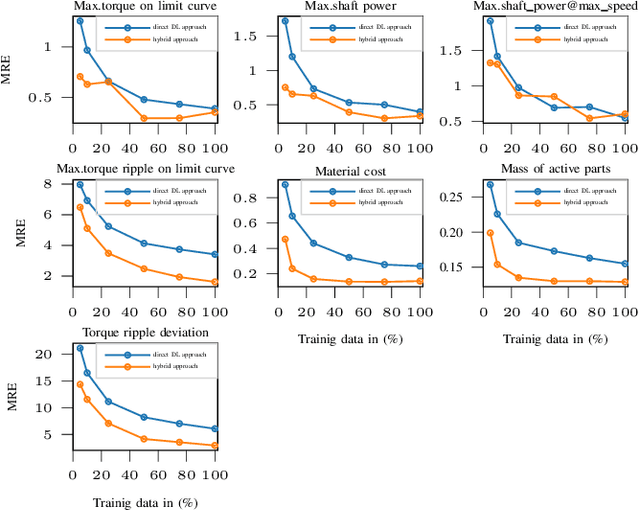

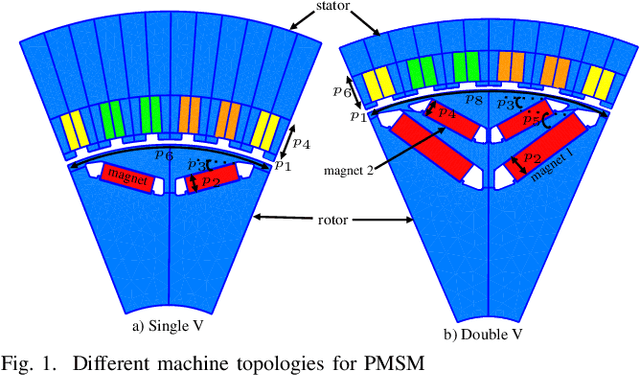

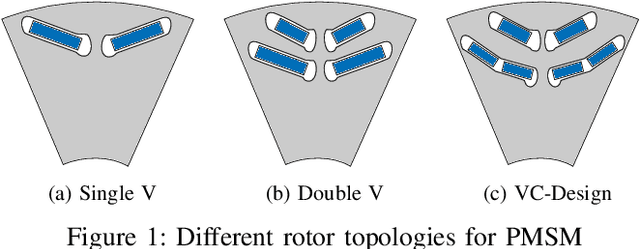

Jun 15, 2023Abstract:Magneto-static finite element (FE) simulations make numerical optimization of electrical machines very time-consuming and computationally intensive during the design stage. In this paper, we present the application of a hybrid data-and physics-driven model for numerical optimization of permanent magnet synchronous machines (PMSM). Following the data-driven supervised training, deep neural network (DNN) will act as a meta-model to characterize the electromagnetic behavior of PMSM by predicting intermediate FE measures. These intermediate measures are then post-processed with various physical models to compute the required key performance indicators (KPIs), e.g., torque, shaft power, and material costs. We perform multi-objective optimization with both classical FE and a hybrid approach using a nature-inspired evolutionary algorithm. We show quantitatively that the hybrid approach maintains the quality of Pareto results better or close to conventional FE simulation-based optimization while being computationally very cheap.

Performance analysis of Electrical Machines based on Electromagnetic System Characterization using Deep Learning

Jan 24, 2022

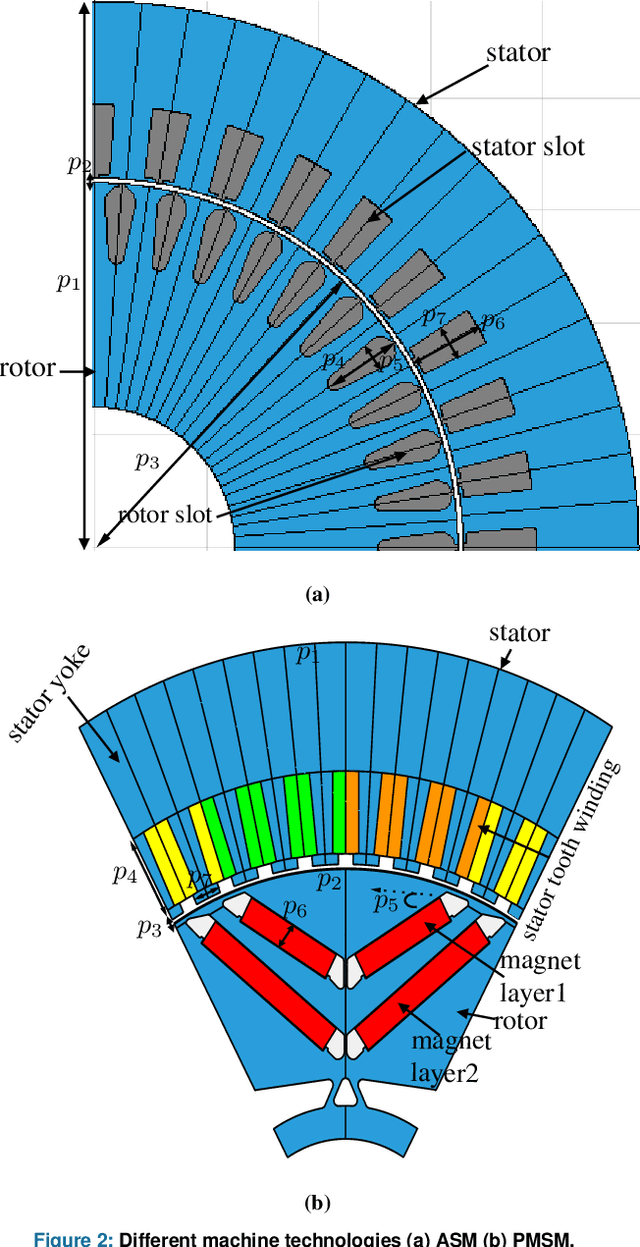

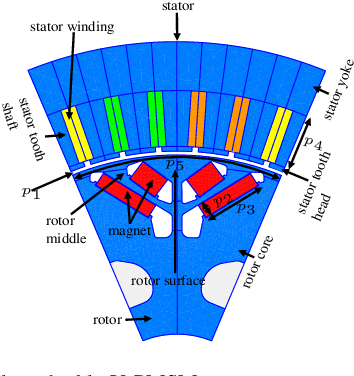

Abstract:The numerical optimization of an electrical machine entails computationally intensive and time-consuming magneto-static finite element (FE) simulation. Generally, this FE-simulation involves varying input geometry, electrical, and material parameters of an electrical machine. The result of the FE simulation characterizes the electromagnetic behavior of the electrical machine. It usually includes nonlinear iron losses and electromagnetic torque and flux at different time-steps for an electrical cycle at each operating point (varying electrical input phase current and control angle). In this paper, we present a novel data-driven deep learning (DL) approach to approximate the electromagnetic behavior of an electrical machine by predicting intermediate measures that include non-linear iron losses, a non-negligible fraction ($\frac{1}{6}$ of a whole electrical period) of the electromagnetic torque and flux at different time-steps for each operating point. The remaining time-steps of the electromagnetic flux and torque for an electrical cycle are estimated by exploiting the magnetic state symmetry of the electrical machine. Then these calculations, along with the system parameters, are fed as input to the physics-based analytical models to estimate characteristic maps and key performance indicators (KPIs) such as material cost, maximum torque, power, torque ripple, etc. The key idea is to train the proposed multi-branch deep neural network (DNN) step by step on a large volume of stored FE data in a supervised manner. Preliminary results exhibit that the predictions of intermediate measures and the subsequent computations of KPIs are close to the ground truth for a new machine design in the input design space. In the end, the quantitative analysis validates that the hybrid approach is more accurate than the existing DNN-based direct prediction of KPIs, which avoids electromagnetic calculations.

Variational Autoencoder based Metamodeling for Multi-Objective Topology Optimization of Electrical Machines

Jan 21, 2022

Abstract:Conventional magneto-static finite element analysis of electrical machine models is time-consuming and computationally expensive. Since each machine topology has a distinct set of parameters, design optimization is commonly performed independently. This paper presents a novel method for predicting Key Performance Indicators (KPIs) of differently parameterized electrical machine topologies at the same time by mapping a high dimensional integrated design parameters in a lower dimensional latent space using a variational autoencoder. After training, via a latent space, the decoder and multi-layer neural network will function as meta-models for sampling new designs and predicting associated KPIs, respectively. This enables parameter-based concurrent multi-topology optimization.

Deep Learning-based Prediction of Key Performance Indicators for Electrical Machine

Jan 23, 2021

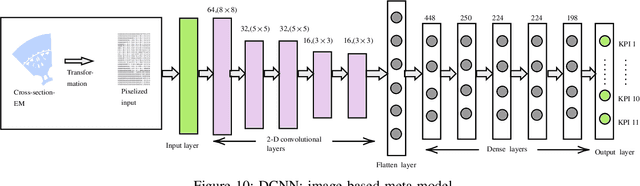

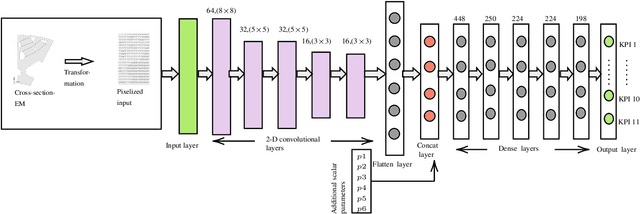

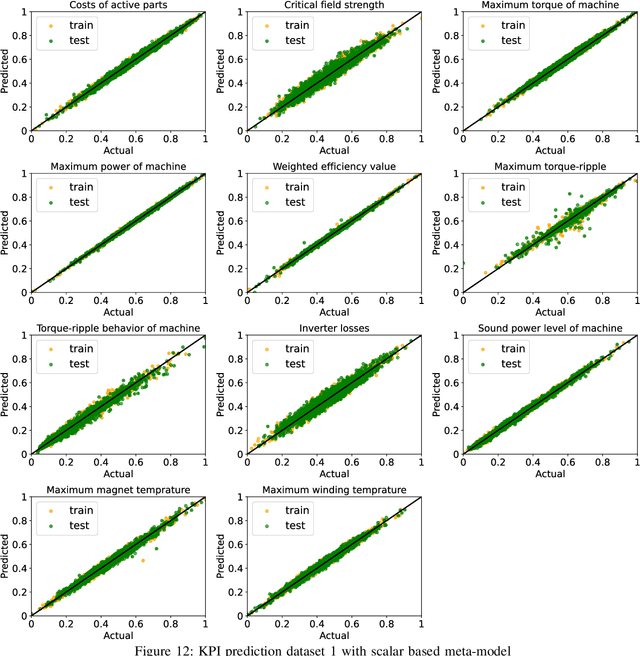

Abstract:The design of an electrical machine can be quantified and evaluated by Key Performance Indicators (KPIs) such as maximum torque, critical field strength, costs of active parts, sound power, etc. Generally, cross-domain tool-chains are used to optimize all the KPIs from different domains (multi-objective optimization) by varying the given input parameters in the largest possible design space. This optimization process involves magneto-static finite element simulation to obtain these decisive KPIs. It makes the whole process a vehemently time-consuming computational task that counts on the availability of resources with the involvement of high computational cost. In this paper, a data-aided, deep learning-based meta-model is employed to predict the KPIs of an electrical machine quickly and with high accuracy to accelerate the full optimization process and reduce its computational costs. The focus is on analyzing various forms of input data that serve as a geometry representation of the machine. Namely, these are the cross-section image of the electrical machine that allows a very general description of the geometry relating to different topologies and the classical way with scalar parametrization of geometry. The impact of the resolution of the image is studied in detail. The results show a high prediction accuracy and proof that the validity of a deep learning-based meta-model to minimize the optimization time. The results also indicate that the prediction quality of an image-based approach can be made comparable to the classical way based on scalar parameters.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge