Detlef Mentrup

AnomalousPatchCore: Exploring the Use of Anomalous Samples in Industrial Anomaly Detection

Aug 27, 2024

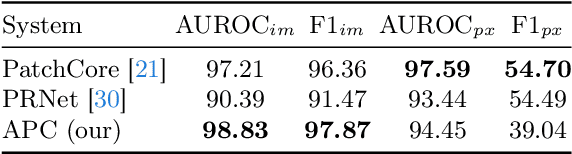

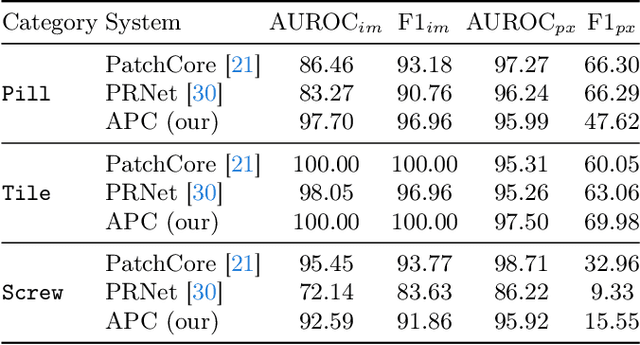

Abstract:Visual inspection, or industrial anomaly detection, is one of the most common quality control types in manufacturing. The task is to identify the presence of an anomaly given an image, e.g., a missing component on an image of a circuit board, for subsequent manual inspection. While industrial anomaly detection has seen a surge in recent years, most anomaly detection methods still utilize knowledge only from normal samples, failing to leverage the information from the frequently available anomalous samples. Additionally, they heavily rely on very general feature extractors pre-trained on common image classification datasets. In this paper, we address these shortcomings and propose the new anomaly detection system AnomalousPatchCore~(APC) based on a feature extractor fine-tuned with normal and anomalous in-domain samples and a subsequent memory bank for identifying unusual features. To fine-tune the feature extractor in APC, we propose three auxiliary tasks that address the different aspects of anomaly detection~(classification vs. localization) and mitigate the effect of the imbalance between normal and anomalous samples. Our extensive evaluation on the MVTec dataset shows that APC outperforms state-of-the-art systems in detecting anomalies, which is especially important in industrial anomaly detection given the subsequent manual inspection. In detailed ablation studies, we further investigate the properties of our APC.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge