Ashwath Prabhu

Encoder-Decoder Networks for Analyzing Thermal and Power Delivery Networks

Oct 27, 2021

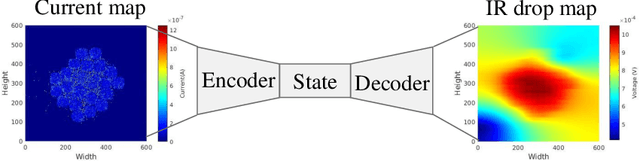

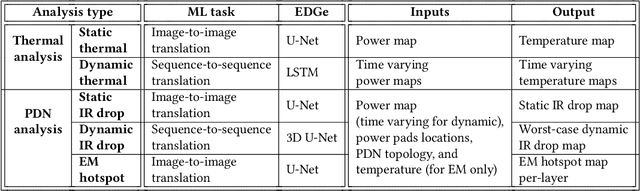

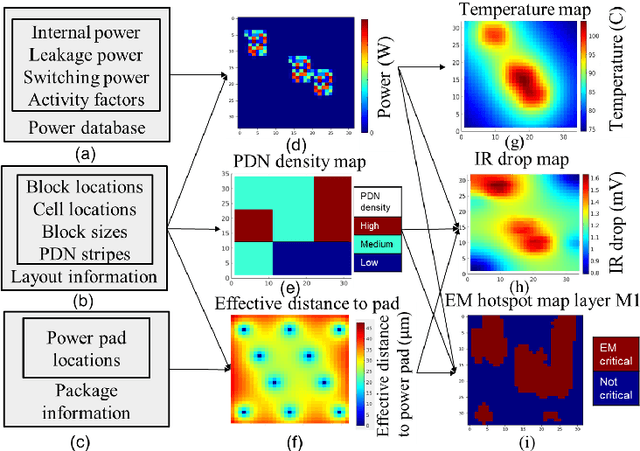

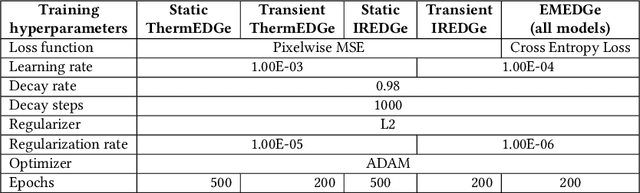

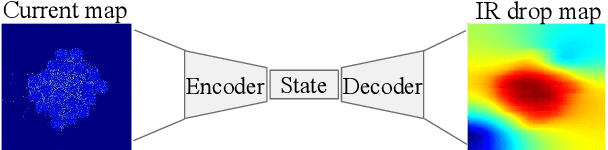

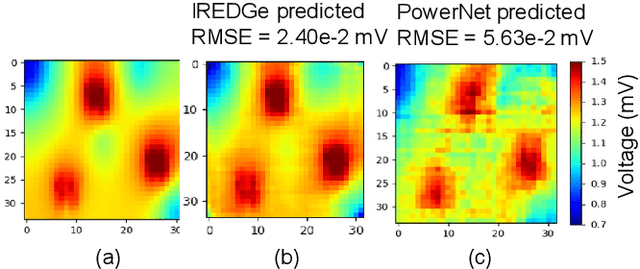

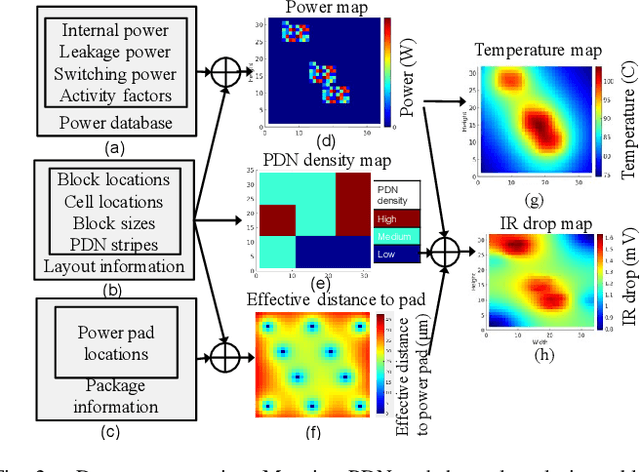

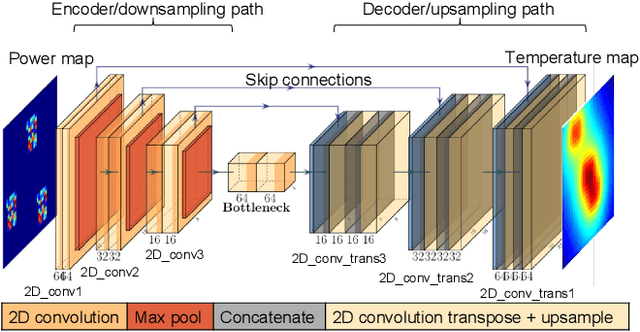

Abstract:Power delivery network (PDN) analysis and thermal analysis are computationally expensive tasks that are essential for successful IC design. Algorithmically, both these analyses have similar computational structure and complexity as they involve the solution to a partial differential equation of the same form. This paper converts these analyses into image-to-image and sequence-to-sequence translation tasks, which allows leveraging a class of machine learning models with an encoder-decoder-based generative (EDGe) architecture to address the time-intensive nature of these tasks. For PDN analysis, we propose two networks: (i) IREDGe: a full-chip static and dynamic IR drop predictor and (ii) EMEDGe: electromigration (EM) hotspot classifier based on input power, power grid distribution, and power pad distribution patterns. For thermal analysis, we propose ThermEDGe, a full-chip static and dynamic temperature estimator based on input power distribution patterns for thermal analysis. These networks are transferable across designs synthesized within the same technology and packing solution. The networks predict on-chip IR drop, EM hotspot locations, and temperature in milliseconds with negligibly small errors against commercial tools requiring several hours.

Thermal and IR Drop Analysis Using Convolutional Encoder-Decoder Networks

Sep 18, 2020

Abstract:Computationally expensive temperature and power grid analyses are required during the design cycle to guide IC design. This paper employs encoder-decoder based generative (EDGe) networks to map these analyses to fast and accurate image-to-image and sequence-to-sequence translation tasks. The network takes a power map as input and outputs the corresponding temperature or IR drop map. We propose two networks: (i) ThermEDGe: a static and dynamic full-chip temperature estimator and (ii) IREDGe: a full-chip static IR drop predictor based on input power, power grid distribution, and power pad distribution patterns. The models are design-independent and must be trained just once for a particular technology and packaging solution. ThermEDGe and IREDGe are demonstrated to rapidly predict the on-chip temperature and IR drop contours in milliseconds (in contrast with commercial tools that require several hours or more) and provide an average error of 0.6% and 0.008% respectively.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge