Get our free extension to see links to code for papers anywhere online!Free add-on: code for papers everywhere!Free add-on: See code for papers anywhere!

Artem Vorontsov

Multivariate Industrial Time Series with Cyber-Attack Simulation: Fault Detection Using an LSTM-based Predictive Data Model

Dec 26, 2016Figures and Tables:

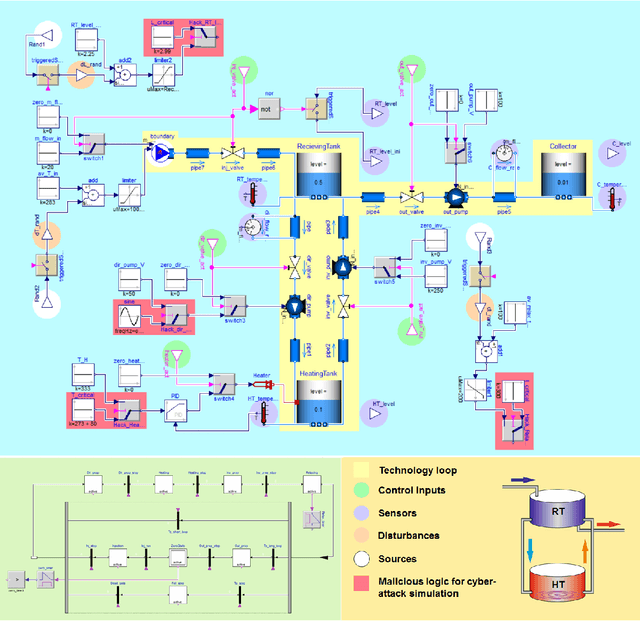

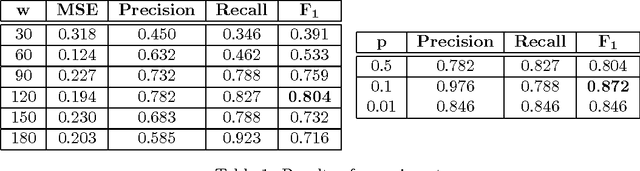

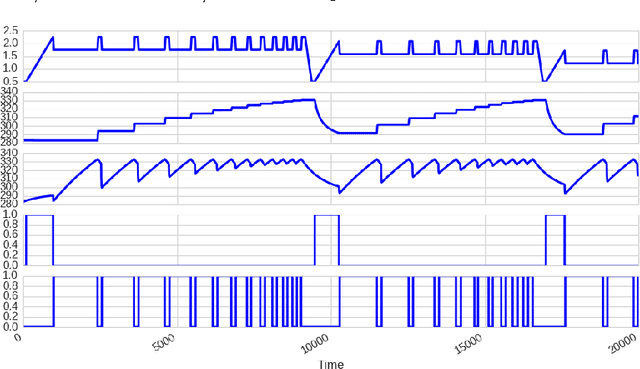

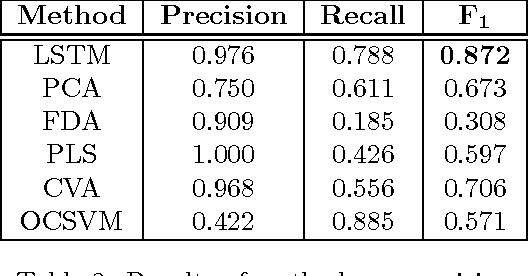

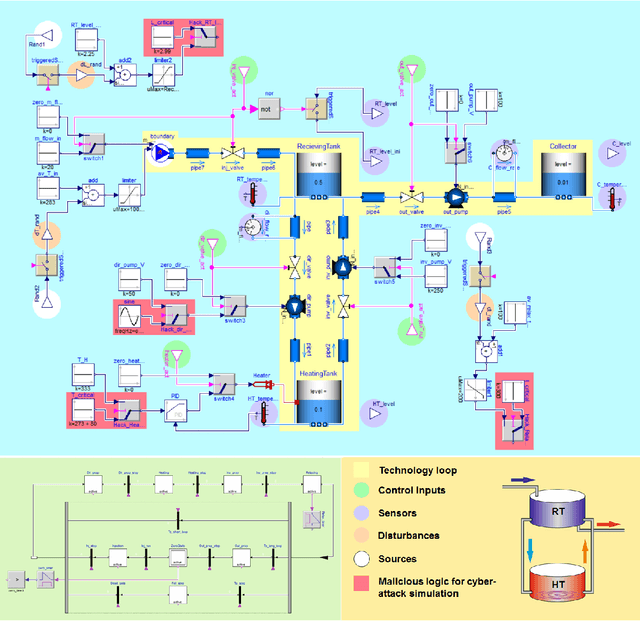

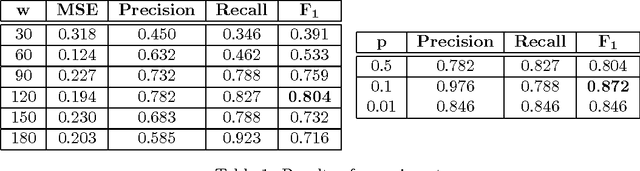

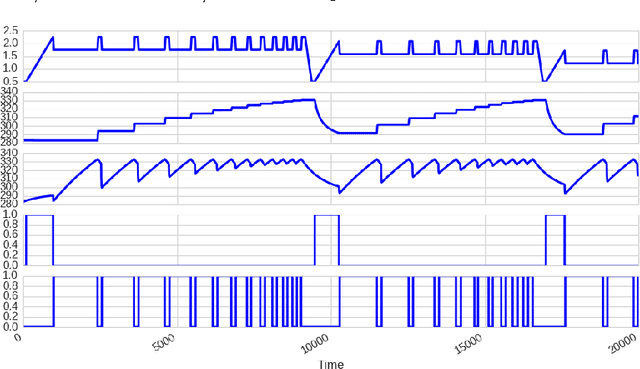

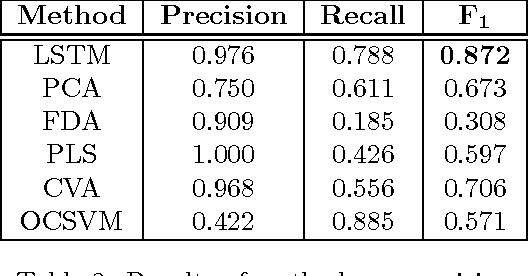

Abstract:We adopted an approach based on an LSTM neural network to monitor and detect faults in industrial multivariate time series data. To validate the approach we created a Modelica model of part of a real gasoil plant. By introducing hacks into the logic of the Modelica model, we were able to generate both the roots and causes of fault behavior in the plant. Having a self-consistent data set with labeled faults, we used an LSTM architecture with a forecasting error threshold to obtain precision and recall quality metrics. The dependency of the quality metric on the threshold level is considered. An appropriate mechanism such as "one handle" was introduced for filtering faults that are outside of the plant operator field of interest.

* Accepted at NIPS Time Series Workshop 2016, Barcelona, Spain, 2016.

Reference update in this version,

https://sites.google.com/site/nipsts2016/NIPS_2016_TSW_paper_10.pdf?attredirects=0&d=1

Via

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge