Arash Dehghan

Joint Matching and Pricing for Crowd-shipping with In-store Customers

Jul 02, 2025

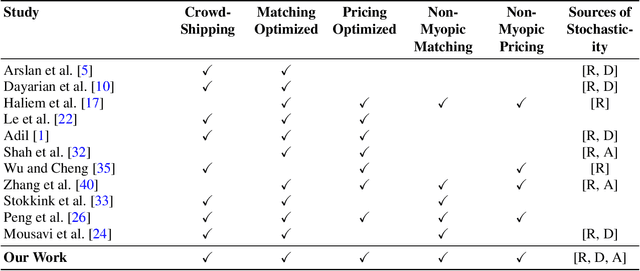

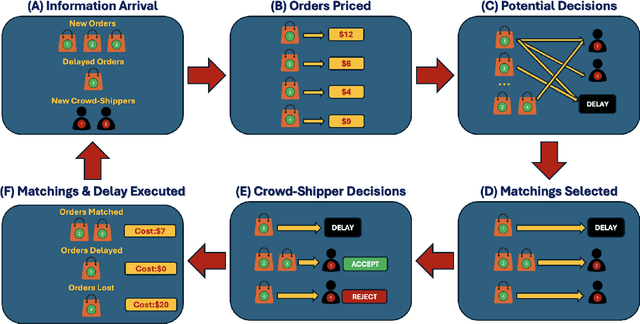

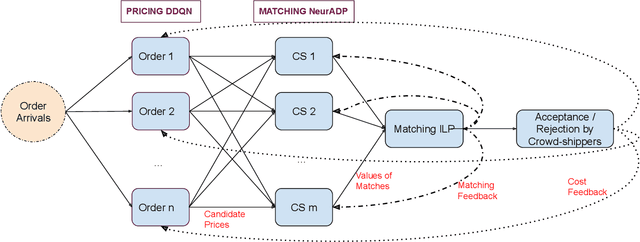

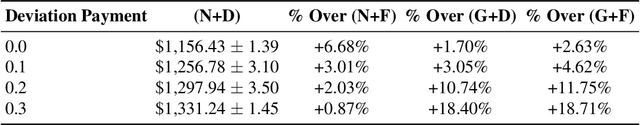

Abstract:This paper examines the use of in-store customers as delivery couriers in a centralized crowd-shipping system, targeting the growing need for efficient last-mile delivery in urban areas. We consider a brick-and-mortar retail setting where shoppers are offered compensation to deliver time-sensitive online orders. To manage this process, we propose a Markov Decision Process (MDP) model that captures key uncertainties, including the stochastic arrival of orders and crowd-shippers, and the probabilistic acceptance of delivery offers. Our solution approach integrates Neural Approximate Dynamic Programming (NeurADP) for adaptive order-to-shopper assignment with a Deep Double Q-Network (DDQN) for dynamic pricing. This joint optimization strategy enables multi-drop routing and accounts for offer acceptance uncertainty, aligning more closely with real-world operations. Experimental results demonstrate that the integrated NeurADP + DDQN policy achieves notable improvements in delivery cost efficiency, with up to 6.7\% savings over NeurADP with fixed pricing and approximately 18\% over myopic baselines. We also show that allowing flexible delivery delays and enabling multi-destination routing further reduces operational costs by 8\% and 17\%, respectively. These findings underscore the advantages of dynamic, forward-looking policies in crowd-shipping systems and offer practical guidance for urban logistics operators.

Dynamic AGV Task Allocation in Intelligent Warehouses

Dec 26, 2023Abstract:This paper explores the integration of Automated Guided Vehicles (AGVs) in warehouse order picking, a crucial and cost-intensive aspect of warehouse operations. The booming AGV industry, accelerated by the COVID-19 pandemic, is witnessing widespread adoption due to its efficiency, reliability, and cost-effectiveness in automating warehouse tasks. This paper focuses on enhancing the picker-to-parts system, prevalent in small to medium-sized warehouses, through the strategic use of AGVs. We discuss the benefits and applications of AGVs in various warehouse tasks, highlighting their transformative potential in improving operational efficiency. We examine the deployment of AGVs by leading companies in the industry, showcasing their varied functionalities in warehouse management. Addressing the gap in research on optimizing operational performance in hybrid environments where humans and AGVs coexist, our study delves into a dynamic picker-to-parts warehouse scenario. We propose a novel approach Neural Approximate Dynamic Programming approach for coordinating a mixed team of human and AGV workers, aiming to maximize order throughput and operational efficiency. This involves innovative solutions for non-myopic decision making, order batching, and battery management. We also discuss the integration of advanced robotics technology in automating the complete order-picking process. Through a comprehensive numerical study, our work offers valuable insights for managing a heterogeneous workforce in a hybrid warehouse setting, contributing significantly to the field of warehouse automation and logistics.

Neural Approximate Dynamic Programming for the Ultra-fast Order Dispatching Problem

Nov 21, 2023Abstract:Same-Day Delivery (SDD) services aim to maximize the fulfillment of online orders while minimizing delivery delays but are beset by operational uncertainties such as those in order volumes and courier planning. Our work aims to enhance the operational efficiency of SDD by focusing on the ultra-fast Order Dispatching Problem (ODP), which involves matching and dispatching orders to couriers within a centralized warehouse setting, and completing the delivery within a strict timeline (e.g., within minutes). We introduce important extensions to ultra-fast ODP such as order batching and explicit courier assignments to provide a more realistic representation of dispatching operations and improve delivery efficiency. As a solution method, we primarily focus on NeurADP, a methodology that combines Approximate Dynamic Programming (ADP) and Deep Reinforcement Learning (DRL), and our work constitutes the first application of NeurADP outside of the ride-pool matching problem. NeurADP is particularly suitable for ultra-fast ODP as it addresses complex one-to-many matching and routing intricacies through a neural network-based VFA that captures high-dimensional problem dynamics without requiring manual feature engineering as in generic ADP methods. We test our proposed approach using four distinct realistic datasets tailored for ODP and compare the performance of NeurADP against myopic and DRL baselines by also making use of non-trivial bounds to assess the quality of the policies. Our numerical results indicate that the inclusion of order batching and courier queues enhances the efficiency of delivery operations and that NeurADP significantly outperforms other methods. Detailed sensitivity analysis with important parameters confirms the robustness of NeurADP under different scenarios, including variations in courier numbers, spatial setup, vehicle capacity, and permitted delay time.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge