Alexander Windmann

Quantifying Robustness: A Benchmarking Framework for Deep Learning Forecasting in Cyber-Physical Systems

Apr 04, 2025

Abstract:Cyber-Physical Systems (CPS) in domains such as manufacturing and energy distribution generate complex time series data crucial for Prognostics and Health Management (PHM). While Deep Learning (DL) methods have demonstrated strong forecasting capabilities, their adoption in industrial CPS remains limited due insufficient robustness. Existing robustness evaluations primarily focus on formal verification or adversarial perturbations, inadequately representing the complexities encountered in real-world CPS scenarios. To address this, we introduce a practical robustness definition grounded in distributional robustness, explicitly tailored to industrial CPS, and propose a systematic framework for robustness evaluation. Our framework simulates realistic disturbances, such as sensor drift, noise and irregular sampling, enabling thorough robustness analyses of forecasting models on real-world CPS datasets. The robustness definition provides a standardized score to quantify and compare model performance across diverse datasets, assisting in informed model selection and architecture design. Through extensive empirical studies evaluating prominent DL architectures (including recurrent, convolutional, attention-based, modular, and structured state-space models) we demonstrate the applicability and effectiveness of our approach. We publicly release our robustness benchmark to encourage further research and reproducibility.

Artificial Intelligence in Industry 4.0: A Review of Integration Challenges for Industrial Systems

May 28, 2024

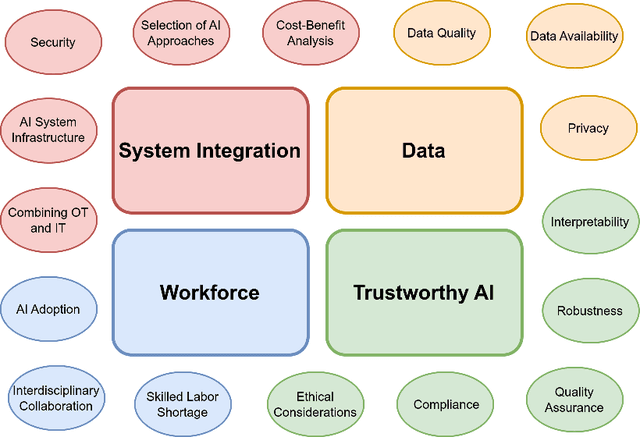

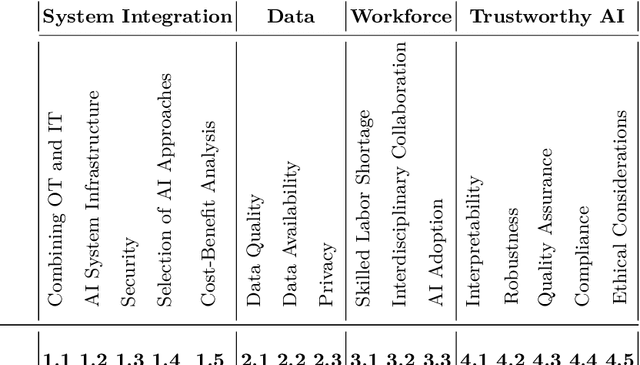

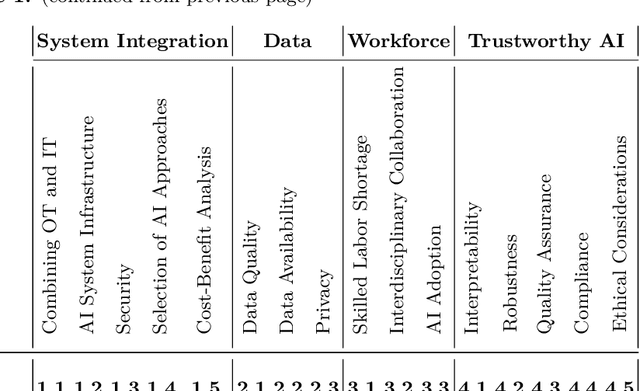

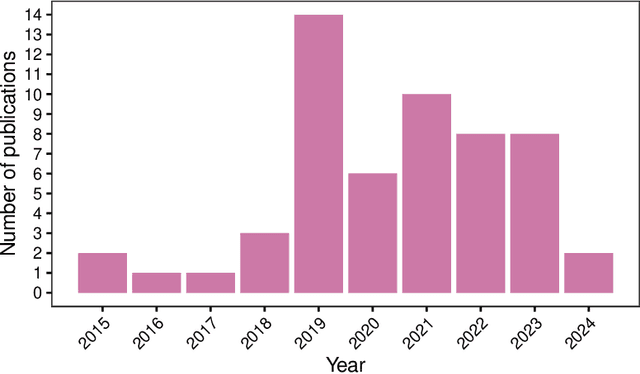

Abstract:In Industry 4.0, Cyber-Physical Systems (CPS) generate vast data sets that can be leveraged by Artificial Intelligence (AI) for applications including predictive maintenance and production planning. However, despite the demonstrated potential of AI, its widespread adoption in sectors like manufacturing remains limited. Our comprehensive review of recent literature, including standards and reports, pinpoints key challenges: system integration, data-related issues, managing workforce-related concerns and ensuring trustworthy AI. A quantitative analysis highlights particular challenges and topics that are important for practitioners but still need to be sufficiently investigated by academics. The paper briefly discusses existing solutions to these challenges and proposes avenues for future research. We hope that this survey serves as a resource for practitioners evaluating the cost-benefit implications of AI in CPS and for researchers aiming to address these urgent challenges.

Robustness and Generalization Performance of Deep Learning Models on Cyber-Physical Systems: A Comparative Study

Jun 13, 2023

Abstract:Deep learning (DL) models have seen increased attention for time series forecasting, yet the application on cyber-physical systems (CPS) is hindered by the lacking robustness of these methods. Thus, this study evaluates the robustness and generalization performance of DL architectures on multivariate time series data from CPS. Our investigation focuses on the models' ability to handle a range of perturbations, such as sensor faults and noise, and assesses their impact on overall performance. Furthermore, we test the generalization and transfer learning capabilities of these models by exposing them to out-of-distribution (OOD) samples. These include deviations from standard system operations, while the core dynamics of the underlying physical system are preserved. Additionally, we test how well the models respond to several data augmentation techniques, including added noise and time warping. Our experimental framework utilizes a simulated three-tank system, proposed as a novel benchmark for evaluating the robustness and generalization performance of DL algorithms in CPS data contexts. The findings reveal that certain DL model architectures and training techniques exhibit superior effectiveness in handling OOD samples and various perturbations. These insights have significant implications for the development of DL models that deliver reliable and robust performance in real-world CPS applications.

On a Uniform Causality Model for Industrial Automation

Sep 20, 2022Abstract:The increasing complexity of Cyber-Physical Systems (CPS) makes industrial automation challenging. Large amounts of data recorded by sensors need to be processed to adequately perform tasks such as diagnosis in case of fault. A promising approach to deal with this complexity is the concept of causality. However, most research on causality has focused on inferring causal relations between parts of an unknown system. Engineering uses causality in a fundamentally different way: complex systems are constructed by combining components with known, controllable behavior. As CPS are constructed by the second approach, most data-based causality models are not suited for industrial automation. To bridge this gap, a Uniform Causality Model for various application areas of industrial automation is proposed, which will allow better communication and better data usage across disciplines. The resulting model describes the behavior of CPS mathematically and, as the model is evaluated on the unique requirements of the application areas, it is shown that the Uniform Causality Model can work as a basis for the application of new approaches in industrial automation that focus on machine learning.

A Research Agenda for AI Planning in the Field of Flexible Production Systems

Jan 14, 2022

Abstract:Manufacturing companies face challenges when it comes to quickly adapting their production control to fluctuating demands or changing requirements. Control approaches that encapsulate production functions as services have shown to be promising in order to increase the flexibility of Cyber-Physical Production Systems. But an existing challenge of such approaches is finding a production plan based on provided functionalities for a demanded product, especially when there is no direct (i.e., syntactic) match between demanded and provided functions. While there is a variety of approaches to production planning, flexible production poses specific requirements that are not covered by existing research. In this contribution, we first capture these requirements for flexible production environments. Afterwards, an overview of current Artificial Intelligence approaches that can be utilized in order to overcome the aforementioned challenges is given. For this purpose, we focus on planning algorithms, but also consider models of production systems that can act as inputs to these algorithms. Approaches from both symbolic AI planning as well as approaches based on Machine Learning are discussed and eventually compared against the requirements. Based on this comparison, a research agenda is derived.

Learning Physical Concepts in Cyber-Physical Systems: A Case Study

Dec 17, 2021

Abstract:Machine Learning (ML) has achieved great successes in recent decades, both in research and in practice. In Cyber-Physical Systems (CPS), ML can for example be used to optimize systems, to detect anomalies or to identify root causes of system failures. However, existing algorithms suffer from two major drawbacks: (i) They are hard to interpret by human experts. (ii) Transferring results from one systems to another (similar) system is often a challenge. Concept learning, or Representation Learning (RepL), is a solution to both of these drawbacks; mimicking the human solution approach to explain-ability and transfer-ability: By learning general concepts such as physical quantities or system states, the model becomes interpretable by humans. Furthermore concepts on this abstract level can normally be applied to a wide range of different systems. Modern ML methods are already widely used in CPS, but concept learning and transfer learning are hardly used so far. In this paper, we provide an overview of the current state of research regarding methods for learning physical concepts in time series data, which is the primary form of sensor data of CPS. We also analyze the most important methods from the current state of the art using the example of a three-tank system. Based on these concrete implementations1, we discuss the advantages and disadvantages of the methods and show for which purpose and under which conditions they can be used.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge