Akshay Dvivedi

Additive Manufacturing Processes Protocol Prediction by Artificial Intelligence using X-ray Computed Tomography data

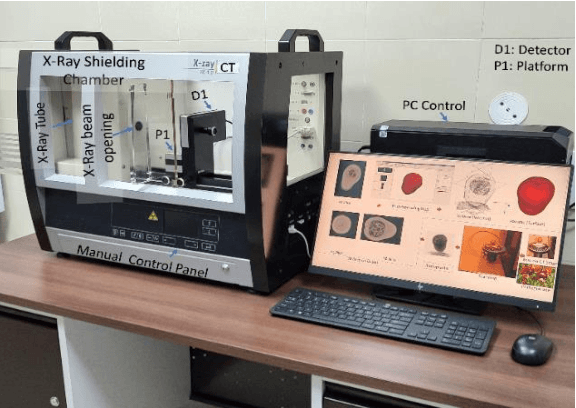

Jan 24, 2025Abstract:The quality of the part fabricated from the Additive Manufacturing (AM) process depends upon the process parameters used, and therefore, optimization is required for apt quality. A methodology is proposed to set these parameters non-iteratively without human intervention. It utilizes Artificial Intelligence (AI) to fully automate the process, with the capability to self-train any apt AI model by further assimilating the training data.This study includes three commercially available 3D printers for soft material printing based on the Material Extrusion (MEX) AM process. The samples are 3D printed for six different AM process parameters obtained by varying layer height and nozzle speed. The novelty part of the methodology is incorporating an AI-based image segmentation step in the decision-making stage that uses quality inspected training data from the Non-Destructive Testing (NDT) method. The performance of the trained AI model is compared with the two software tools based on the classical thresholding method. The AI-based Artificial Neural Network (ANN) model is trained from NDT-assessed and AI-segmented data to automate the selection of optimized process parameters. The AI-based model is 99.3 % accurate, while the best available commercial classical image method is 83.44 % accurate. The best value of overall R for training ANN is 0.82. The MEX process gives a 22.06 % porosity error relative to the design. The NDT-data trained two AI models integrated into a series pipeline for optimal process parameters are proposed and verified by classical optimization and mechanical testing methods.

Characterization of 3D Printers and X-Ray Computerized Tomography

May 27, 2022

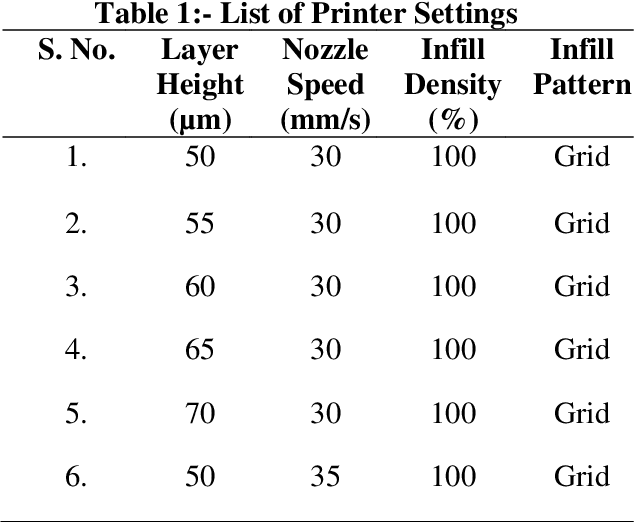

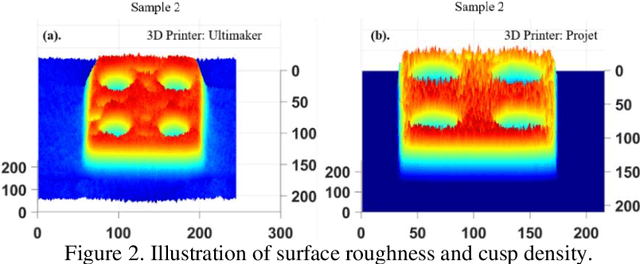

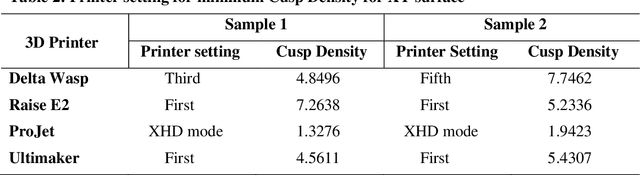

Abstract:The 3D printing process flow requires several inputs for the best printing quality. These settings may vary from sample to sample, printer to printer, and depend upon users' previous experience. The involved operational parameters for 3D Printing are varied to test the optimality. Thirty-eight samples are printed using four commercially available 3D printers, namely: (a) Ultimaker 2 Extended+, (b) Delta Wasp, (c) Raise E2, and (d) ProJet MJP. The sample profiles contain uniform and non-uniform distribution of the assorted size of cubes and spheres with a known amount of porosity. These samples are scanned using X-Ray Computed Tomography system. Functional Imaging analysis is performed using AI-based segmentation codes to (a) characterize these 3D printers and (b) find Three-dimensional surface roughness of three teeth and one sandstone pebble (from riverbed) with naturally deposited layers is also compared with printed sample values. Teeth has best quality. It is found that ProJet MJP gives the best quality of printed samples with the least amount of surface roughness and almost near to the actual porosity value. As expected, 100% infill density value, best spatial resolution for printing or Layer height, and minimum nozzle speed give the best quality of 3D printing.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge