A. R. Singer

Michigan Engineering Services

Temporal clustering network for self-diagnosing faults from vibration measurements

Jun 16, 2020

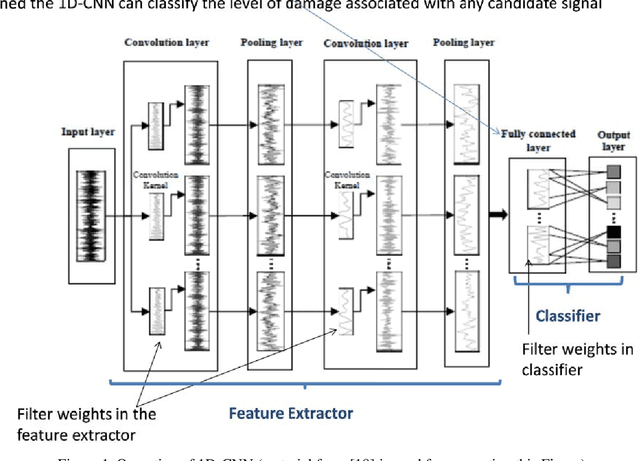

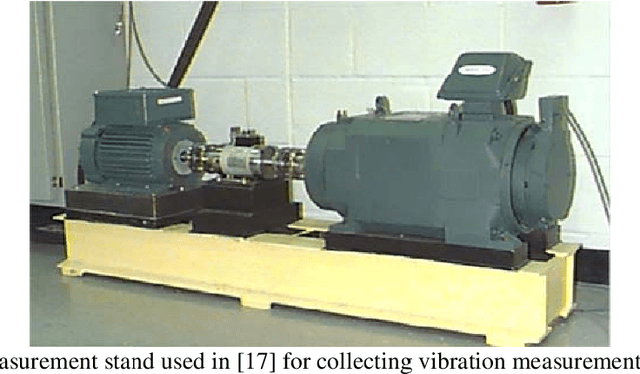

Abstract:There is a need to build intelligence in operating machinery and use data analysis on monitored signals in order to quantify the health of the operating system and self-diagnose any initiations of fault. Built-in control procedures can automatically take corrective actions in order to avoid catastrophic failure when a fault is diagnosed. This paper presents a Temporal Clustering Network (TCN) capability for processing acceleration measurement(s) made on the operating system (i.e. machinery foundation, machinery casing, etc.), or any other type of temporal signals, and determine based on the monitored signal when a fault is at its onset. The new capability uses: one-dimensional convolutional neural networks (1D-CNN) for processing the measurements; unsupervised learning (i.e. no labeled signals from the different operating conditions and no signals at pristine vs. damaged conditions are necessary for training the 1D-CNN); clustering (i.e. grouping signals in different clusters reflective of the operating conditions); and statistical analysis for identifying fault signals that are not members of any of the clusters associated with the pristine operating conditions. A case study demonstrating its operation is included in the paper. Finally topics for further research are identified.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge