Workload Prediction of Business Processes -- An Approach Based on Process Mining and Recurrent Neural Networks

Paper and Code

Feb 14, 2020

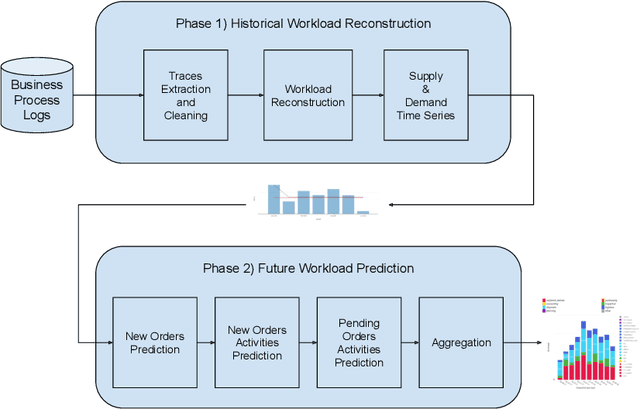

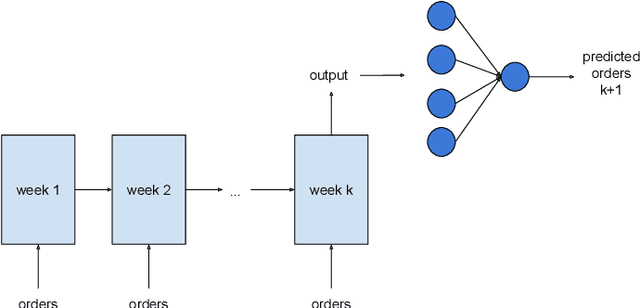

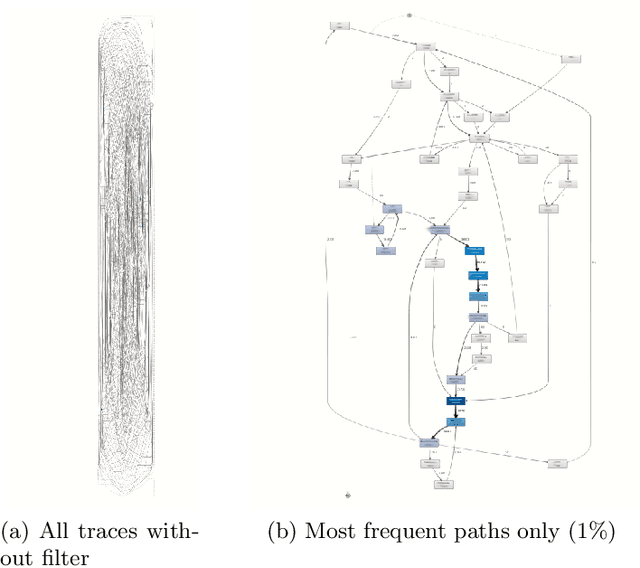

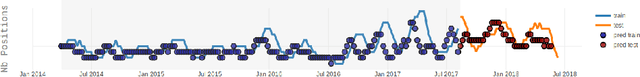

Recent advances in the interconnectedness and digitization of industrial machines, known as Industry 4.0, pave the way for new analytical techniques. Indeed, the availability and the richness of production-related data enables new data-driven methods. In this paper, we propose a process mining approach augmented with artificial intelligence that (1) reconstructs the historical workload of a company and (2) predicts the workload using neural networks. Our method relies on logs, representing the history of business processes related to manufacturing. These logs are used to quantify the supply and demand and are fed into a recurrent neural network model to predict customer orders. The corresponding activities to fulfill these orders are then sampled from history with a replay mechanism, based on criteria such as trace frequency and activities similarity. An evaluation and illustration of the method is performed on the administrative processes of Heraeus Materials SA. The workload prediction on a one-year test set achieves an MAPE score of 19% for a one-week forecast. The case study suggests a reasonable accuracy and confirms that a good understanding of the historical workload combined to articulated predictions are of great help for supporting management decisions and can decrease costs with better resources planning on a medium-term level.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge