Towards zero-configuration condition monitoring based on dictionary learning

Paper and Code

Feb 12, 2015

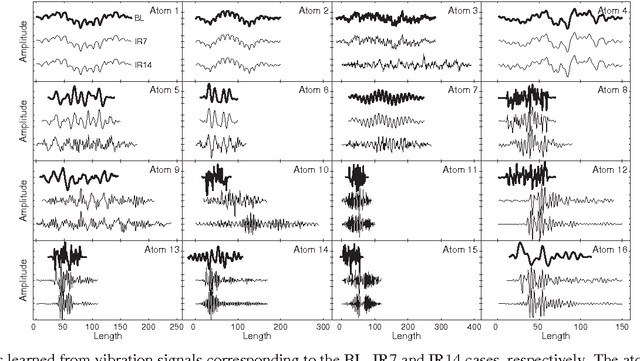

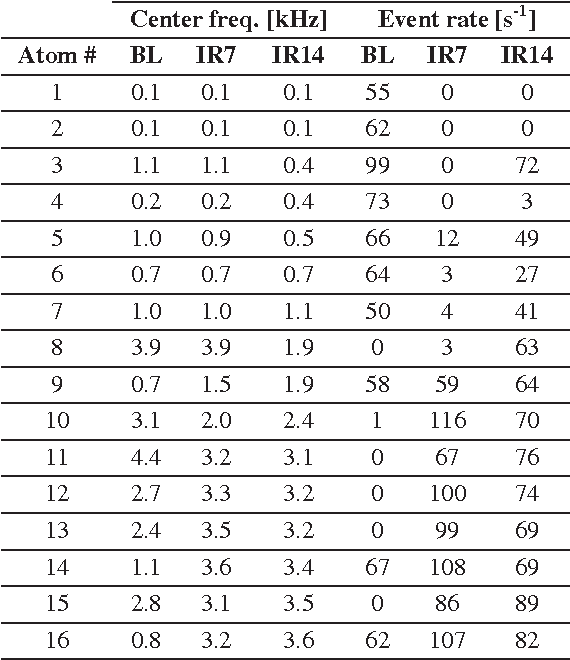

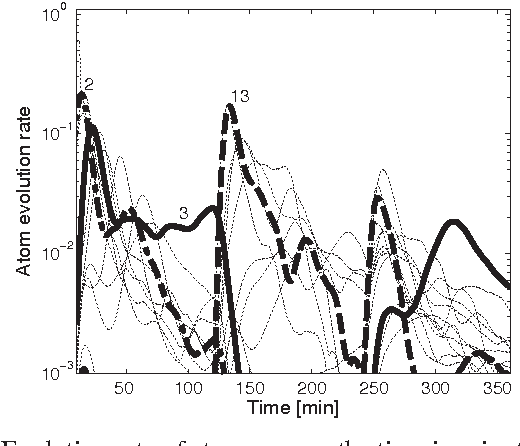

Condition-based predictive maintenance can significantly improve overall equipment effectiveness provided that appropriate monitoring methods are used. Online condition monitoring systems are customized to each type of machine and need to be reconfigured when conditions change, which is costly and requires expert knowledge. Basic feature extraction methods limited to signal distribution functions and spectra are commonly used, making it difficult to automatically analyze and compare machine conditions. In this paper, we investigate the possibility to automate the condition monitoring process by continuously learning a dictionary of optimized shift-invariant feature vectors using a well-known sparse approximation method. We study how the feature vectors learned from a vibration signal evolve over time when a fault develops within a ball bearing of a rotating machine. We quantify the adaptation rate of learned features and find that this quantity changes significantly in the transitions between normal and faulty states of operation of the ball bearing.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge