Thermal Neural Networks: Lumped-Parameter Thermal Modeling With State-Space Machine Learning

Paper and Code

Apr 08, 2021

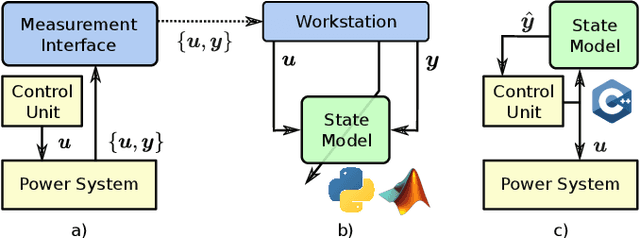

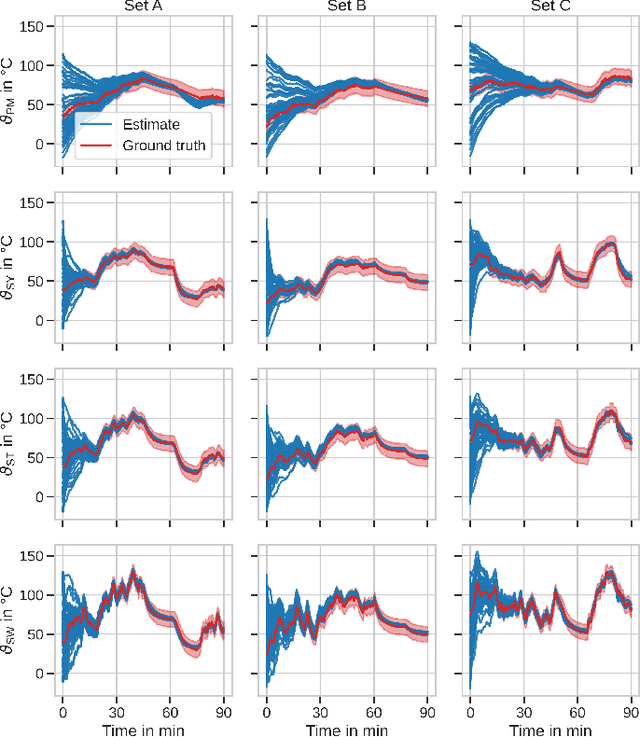

With electric power systems becoming more compact and increasingly powerful, the relevance of thermal stress especially during overload operation is expected to increase ceaselessly. Whenever critical temperatures cannot be measured economically on a sensor base, a thermal model lends itself to estimate those unknown quantities. Thermal models for electric power systems are usually required to be both, real-time capable and of high estimation accuracy. Moreover, ease of implementation and time to production play an increasingly important role. In this work, the thermal neural network (TNN) is introduced, which unifies both, consolidated knowledge in the form of heat-transfer-based lumped-parameter models, and data-driven nonlinear function approximation with supervised machine learning. A quasi-linear parameter-varying system is identified solely from empirical data, where relationships between scheduling variables and system matrices are inferred statistically and automatically. At the same time, a TNN has physically interpretable states through its state-space representation, is end-to-end trainable -- similar to deep learning models -- with automatic differentiation, and requires no material, geometry, nor expert knowledge for its design. Experiments on an electric motor data set show that a TNN achieves higher temperature estimation accuracies than previous white-/grey- or black-box models with a mean squared error of $3.18~\text{K}^2$ and a worst-case error of $5.84~\text{K}$ at 64 model parameters.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge