Synthetic training data generation for deep learning based quality inspection

Paper and Code

Apr 07, 2021

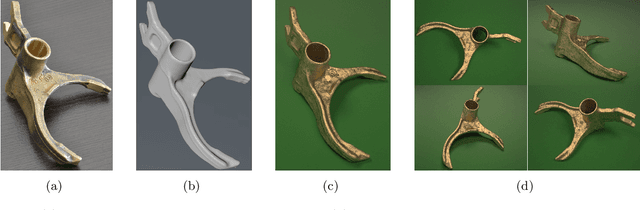

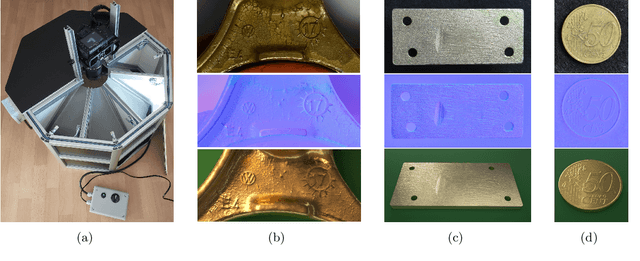

Deep learning is now the gold standard in computer vision-based quality inspection systems. In order to detect defects, supervised learning is often utilized, but necessitates a large amount of annotated images, which can be costly: collecting, cleaning, and annotating the data is tedious and limits the speed at which a system can be deployed as everything the system must detect needs to be observed first. This can impede the inspection of rare defects, since very few samples can be collected by the manufacturer. In this work, we focus on simulations to solve this issue. We first present a generic simulation pipeline to render images of defective or healthy (non defective) parts. As metallic parts can be highly textured with small defects like holes, we design a texture scanning and generation method. We assess the quality of the generated images by training deep learning networks and by testing them on real data from a manufacturer. We demonstrate that we can achieve encouraging results on real defect detection using purely simulated data. Additionally, we are able to improve global performances by concatenating simulated and real data, showing that simulations can complement real images to boost performances. Lastly, using domain adaptation techniques helps improving slightly our final results.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge