Structured Pneumatic Fingerpads for Actively Tunable Grip Friction

Paper and Code

Feb 02, 2025

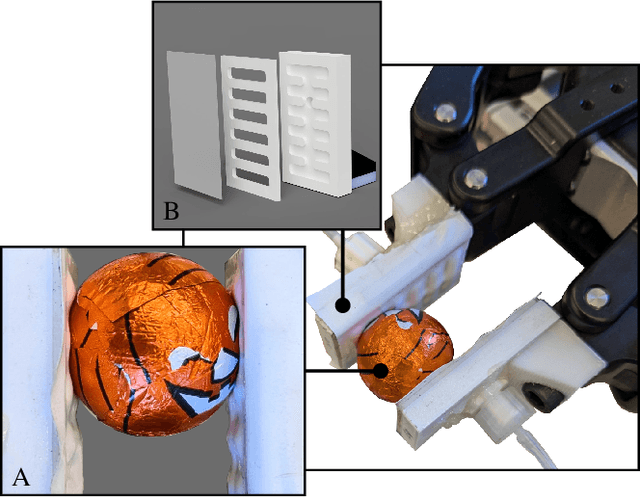

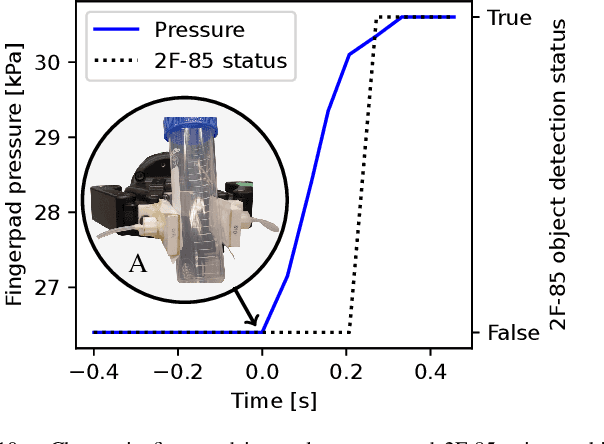

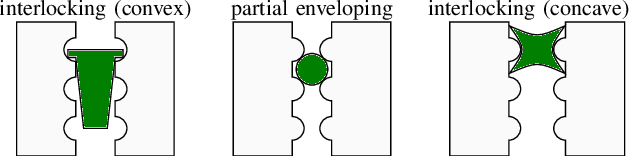

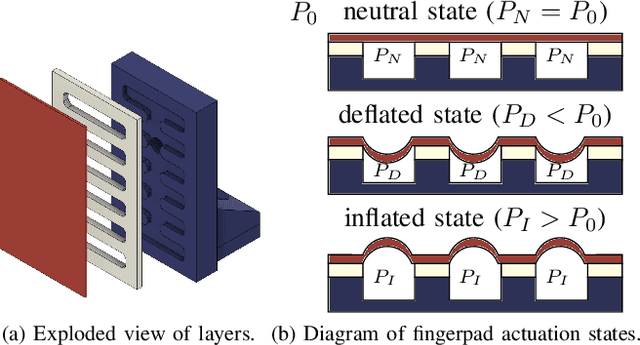

Grip surfaces with tunable friction can actively modify contact conditions, enabling transitions between higher- and lower-friction states for grasp adjustment. Friction can be increased to grip securely and then decreased to gently release (e.g., for handovers) or manipulate in-hand. Recent friction-tuning surface designs using soft pneumatic chambers show good control over grip friction; however, most require complex fabrication processes and/or custom gripper hardware. We present a practical structured fingerpad design for friction tuning that uses less than \$1 USD of materials, takes only seconds to repair, and is easily adapted to existing grippers. Our design uses surface morphology changes to tune friction. The fingerpad is actuated by pressurizing its internal chambers, thereby deflecting its flexible grip surface out from or into these chambers. We characterize the friction-tuning capabilities of our design by measuring the shear force required to pull an object from a gripper equipped with two independently actuated fingerpads. Our results show that varying actuation pressure and timing changes the magnitude of friction forces on a gripped object by up to a factor of 2.8. We demonstrate additional features including macro-scale interlocking behaviour and pressure-based object detection.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge