Soft Sensing Regression Model: from Sensor to Wafer Metrology Forecasting

Paper and Code

Jan 21, 2023

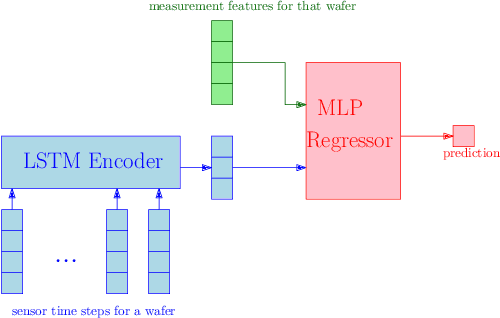

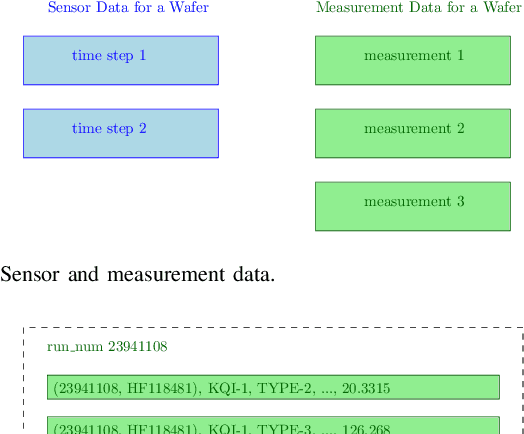

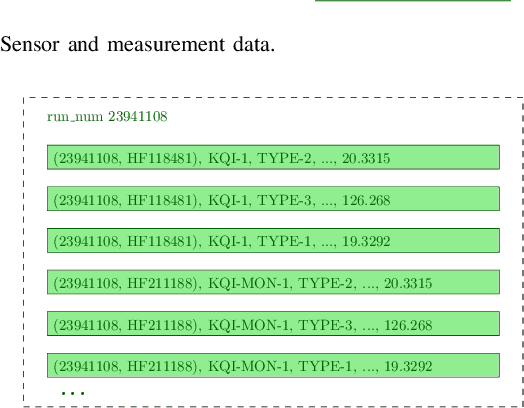

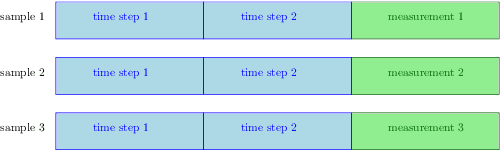

The semiconductor industry is one of the most technology-evolving and capital-intensive market sectors. Effective inspection and metrology are necessary to improve product yield, increase product quality and reduce costs. In recent years, many semiconductor manufacturing equipments are equipped with sensors to facilitate real-time monitoring of the production process. These production-state and equipment-state sensor data provide an opportunity to practice machine-learning technologies in various domains, such as anomaly/fault detection, maintenance scheduling, quality prediction, etc. In this work, we focus on the task of soft sensing regression, which uses sensor data to predict impending inspection measurements that used to be measured in wafer inspection and metrology systems. We proposed an LSTM-based regressor and designed two loss functions for model training. Although engineers may look at our prediction errors in a subjective manner, a new piece-wise evaluation metric was proposed for assessing model accuracy in a mathematical way. The experimental results demonstrated that the proposed model can achieve accurate and early prediction of various types of inspections in complicated manufacturing processes.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge