Self-Replicating Strands that Self-Assemble into User-Specified Meshes

Paper and Code

Feb 22, 2005

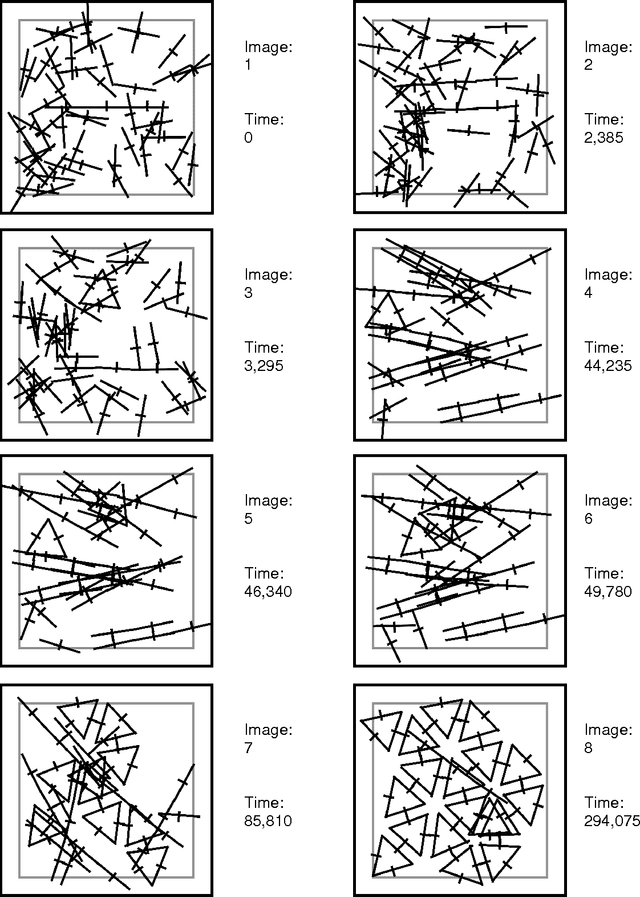

It has been argued that a central objective of nanotechnology is to make products inexpensively, and that self-replication is an effective approach to very low-cost manufacturing. The research presented here is intended to be a step towards this vision. In previous work (JohnnyVon 1.0), we simulated machines that bonded together to form self-replicating strands. There were two types of machines (called types 0 and 1), which enabled strands to encode arbitrary bit strings. However, the information encoded in the strands had no functional role in the simulation. The information was replicated without being interpreted, which was a significant limitation for potential manufacturing applications. In the current work (JohnnyVon 2.0), the information in a strand is interpreted as instructions for assembling a polygonal mesh. There are now four types of machines and the information encoded in a strand determines how it folds. A strand may be in an unfolded state, in which the bonds are straight (although they flex slightly due to virtual forces acting on the machines), or in a folded state, in which the bond angles depend on the types of machines. By choosing the sequence of machine types in a strand, the user can specify a variety of polygonal shapes. A simulation typically begins with an initial unfolded seed strand in a soup of unbonded machines. The seed strand replicates by bonding with free machines in the soup. The child strands fold into the encoded polygonal shape, and then the polygons drift together and bond to form a mesh. We demonstrate that a variety of polygonal meshes can be manufactured in the simulation, by simply changing the sequence of machine types in the seed.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge