Safety Controller Synthesis for Collaborative Robots

Paper and Code

Jul 07, 2020

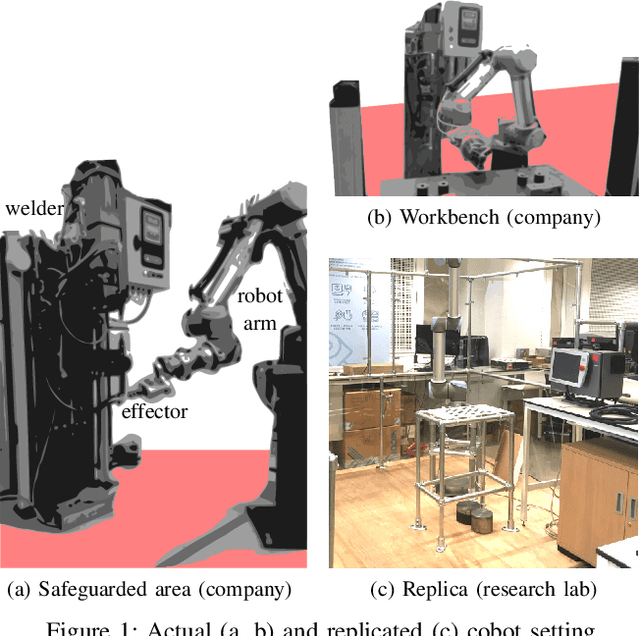

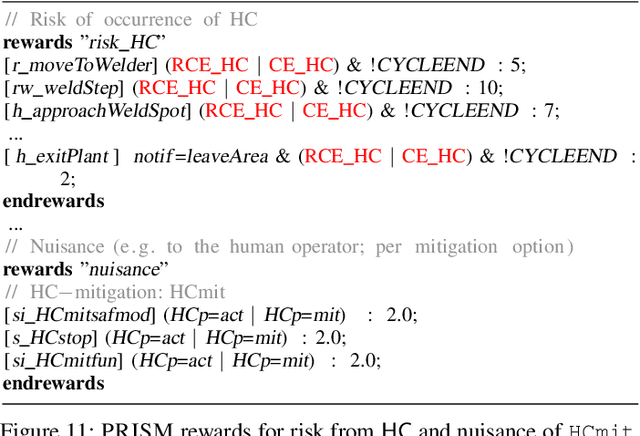

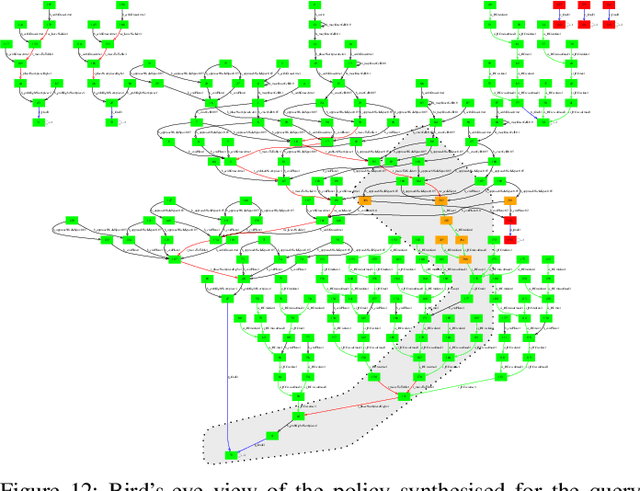

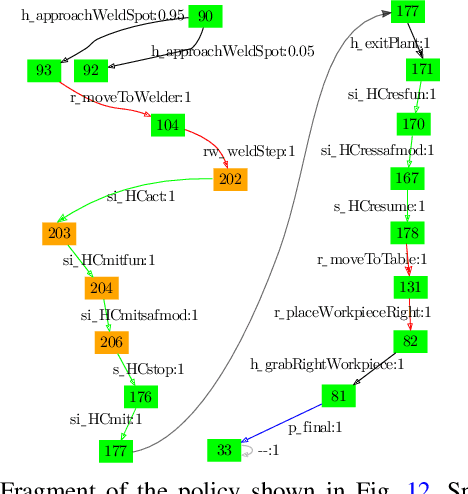

In human-robot collaboration (HRC), software-based automatic safety controllers (ASCs) are used in various forms (e.g. shutdown mechanisms, emergency brakes, interlocks) to improve operational safety. Complex robotic tasks and increasingly close human-robot interaction pose new challenges to ASC developers and certification authorities. Key among these challenges is the need to assure the correctness of ASCs under reasonably weak assumptions. To address this need, we introduce and evaluate a tool-supported ASC synthesis method for HRC in manufacturing. Our ASC synthesis is: (i) informed by the manufacturing process, risk analysis, and regulations; (ii) formally verified against correctness criteria; and (iii) selected from a design space of feasible controllers according to a set of optimality criteria. The synthesised ASC can detect the occurrence of hazards, move the process into a safe state, and, in certain circumstances, return the process to an operational state from which it can resume its original task.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge