Radar-based Materials Classification Using Deep Wavelet Scattering Transform: A Comparison of Centimeter vs. Millimeter Wave Units

Paper and Code

Feb 08, 2022

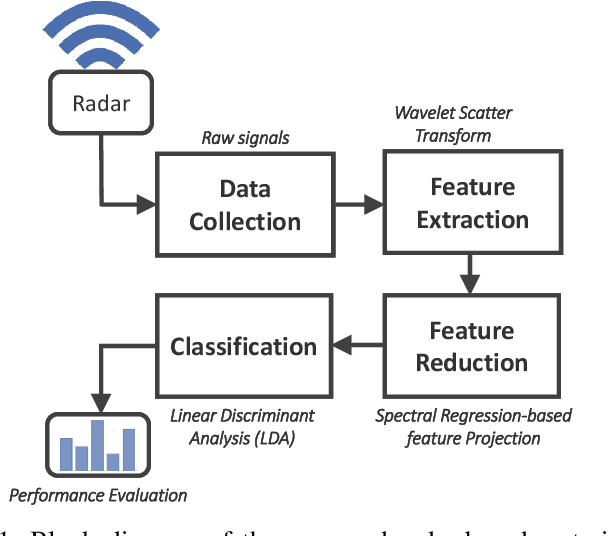

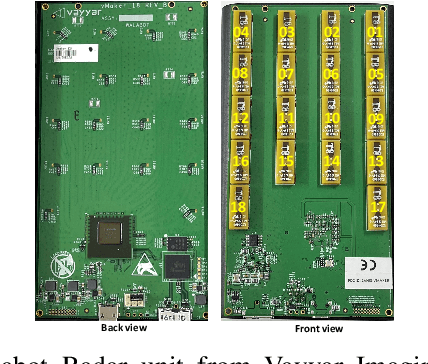

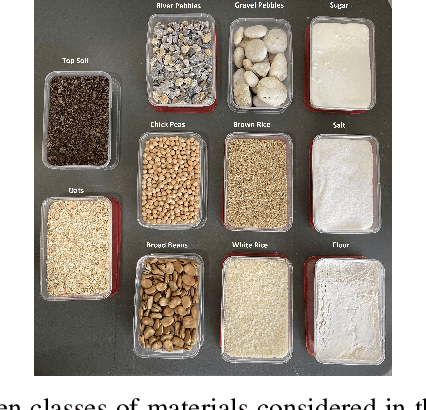

Radar-based materials detection received significant attention in recent years for its potential inclusion in consumer and industrial applications like object recognition for grasping and manufacturing quality assurance and control. Several radar publications were developed for material classification under controlled settings with specific materials' properties and shapes. Recent literature has challenged the earlier findings on radars-based materials classification claiming that earlier solutions are not easily scaled to industrial applications due to a variety of real-world issues. Published experiments on the impact of these factors on the robustness of the extracted radar-based traditional features have already demonstrated that the application of deep neural networks can mitigate, to some extent, the impact to produce a viable solution. However, previous studies lacked an investigation of the usefulness of lower frequency radar units, specifically <10GHz, against the higher range units around and above 60GHz. This research considers two radar units with different frequency ranges: Walabot-3D (6.3-8 GHz) cm-wave and IMAGEVK-74 (62-69 GHz) mm-wave imaging units by Vayyar Imaging. A comparison is presented on the applicability of each unit for material classification. This work extends upon previous efforts, by applying deep wavelet scattering transform for the identification of different materials based on the reflected signals. In the wavelet scattering feature extractor, data is propagated through a series of wavelet transforms, nonlinearities, and averaging to produce low-variance representations of the reflected radar signals. This work is unique in comparison of the radar units and algorithms in material classification and includes real-time demonstrations that show strong performance by both units, with increased robustness offered by the cm-wave radar unit.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge