Quick Learning Mechanism with Cross-Domain Adaptation for Intelligent Fault Diagnosis

Paper and Code

Mar 16, 2021

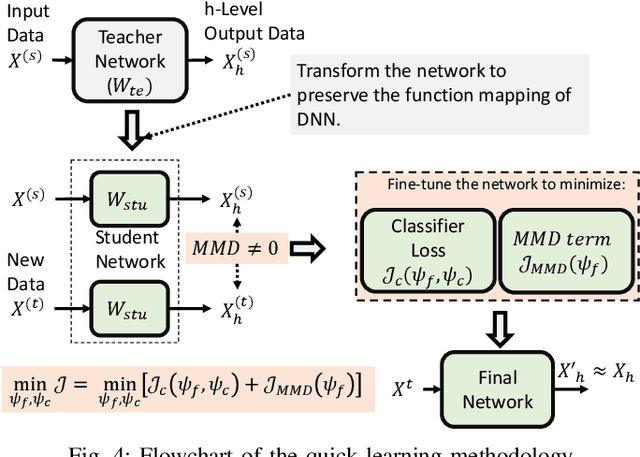

This paper presents a quick learning mechanism for intelligent fault diagnosis of rotating machines operating under changeable working conditions. Since real case machines in industries run under different operating conditions, the deep learning model trained for a laboratory case machine fails to perform well for the fault diagnosis using recorded data from real case machines. It poses the need of training a new diagnostic model for the fault diagnosis of the real case machine under every new working condition. Therefore, there is a need for a mechanism that can quickly transform the existing diagnostic model for machines operating under different conditions. we propose a quick learning method with Net2Net transformation followed by a fine-tuning method to cancel/minimize the maximum mean discrepancy of the new data to the previous one. This transformation enables us to create a new network with any architecture almost ready to be used for the new dataset. The effectiveness of the proposed fault diagnosis method has been demonstrated on the CWRU dataset, IMS bearing dataset, and Paderborn university dataset. We have shown that the diagnostic model trained for CWRU data at zero load can be used to quickly train another diagnostic model for the CWRU data at different loads and also for the IMS dataset. Using the dataset provided by Paderborn university, it has been validated that the diagnostic model trained on artificially damaged fault dataset can be used for quickly training another model for real damage dataset.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge