Precision Glass Thermoforming Assisted by Neural Networks

Paper and Code

Nov 11, 2024

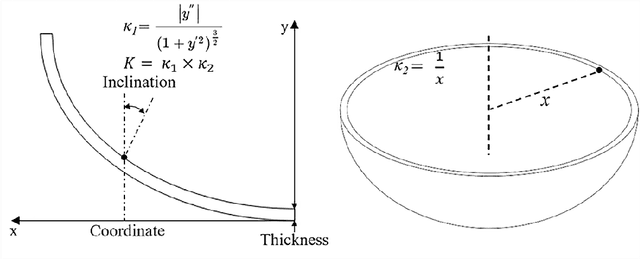

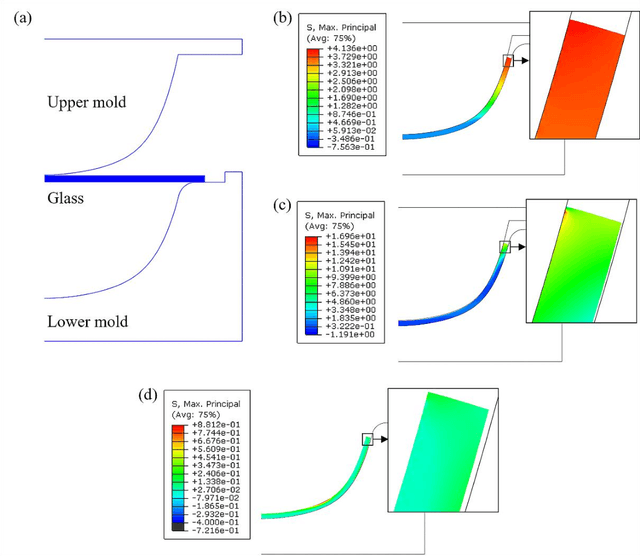

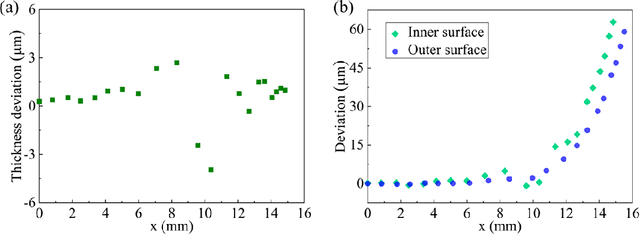

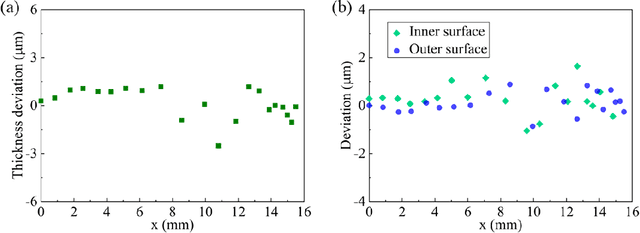

Glass with good processability, chemical inertness, and optical transparency has been widely used in optical and aesthetic products, many of which require curve pro-files with high precision. To meet the increasingly tightened geometrical tolerances and fast product updating rates, the traditional approach of developing a thermoform-ing process through trials and errors can cause a large waste of time and resources and often end up with failure. Hence, there is a need to develop an efficient predictive model, replacing the costly simulations or experiments, to assist the design of preci-sion glass thermoforming. In this work, we report a dimensionless back-propagation neural network (BPNN) that can adequately predict the form errors and thus compen-sate for these errors in mold design to achieve precision glass molding. Based on the precision molds, also discussed is the issue of error magnification considering that cover glass for AR/VR glasses or smartphones, with extremely large scale of produc-tion, may require a lower level of mold machining accuracy. It is expected that this BPNN will also be implementable in the glass-manufacturing industry, i.e., trained using industrial data for precision mold designs.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge