Multi-Modal Data Fusion for Moisture Content Prediction in Apple Drying

Paper and Code

Apr 10, 2025

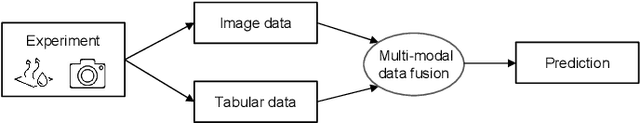

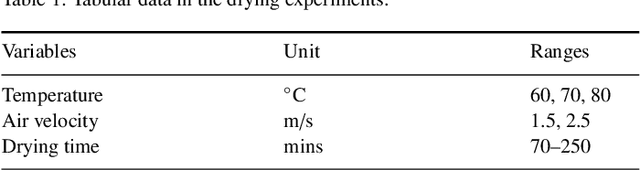

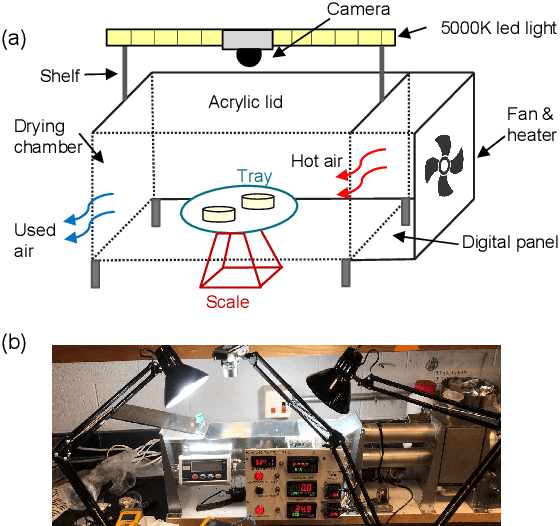

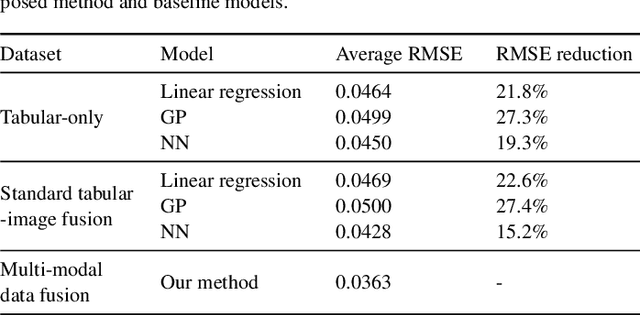

Fruit drying is widely used in food manufacturing to reduce product moisture, ensure product safety, and extend product shelf life. Accurately predicting final moisture content (MC) is critically needed for quality control of drying processes. State-of-the-art methods can build deterministic relationships between process parameters and MC, but cannot adequately account for inherent process variabilities that are ubiquitous in fruit drying. To address this gap, this paper presents a novel multi-modal data fusion framework to effectively fuse two modalities of data: tabular data (process parameters) and high-dimensional image data (images of dried apple slices) to enable accurate MC prediction. The proposed modeling architecture permits flexible adjustment of information portion from tabular and image data modalities. Experimental validation shows that the multi-modal approach improves predictive accuracy substantially compared to state-of-the-art methods. The proposed method reduces root-mean-squared errors by 19.3%, 24.2%, and 15.2% over tabular-only, image-only, and standard tabular-image fusion models, respectively. Furthermore, it is demonstrated that our method is robust in varied tabular-image ratios and capable of effectively capturing inherent small-scale process variabilities. The proposed framework is extensible to a variety of other drying technologies.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge