Monitoring nonstationary processes based on recursive cointegration analysis and elastic weight consolidation

Paper and Code

Jan 21, 2021

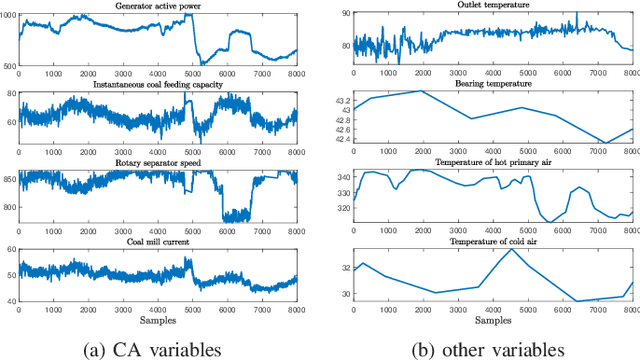

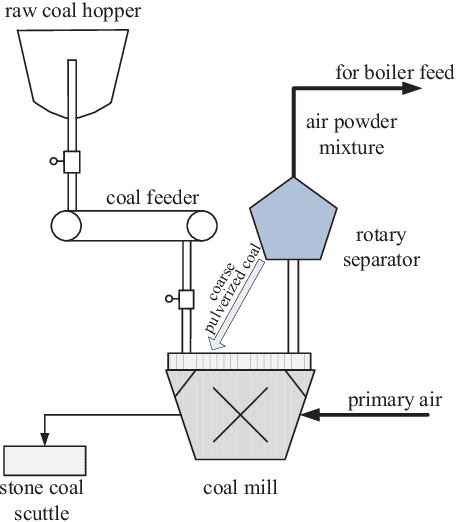

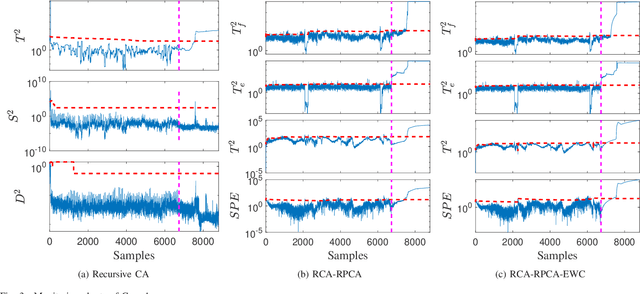

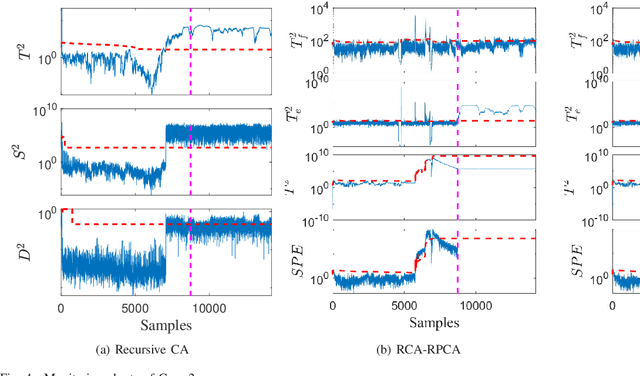

This paper considers the problem of nonstationary process monitoring under frequently varying operating conditions. Traditional approaches generally misidentify the normal dynamic deviations as faults and thus lead to high false alarms. Besides, they generally consider single relatively steady operating condition and suffer from the catastrophic forgetting issue when learning successive operating conditions. In this paper, recursive cointegration analysis (RCA) is first proposed to distinguish the real faults from normal systems changes, where the model is updated once a new normal sample arrives and can adapt to slow change of cointegration relationship. Based on the long-term equilibrium information extracted by RCA, the remaining short-term dynamic information is monitored by recursive principal component analysis (RPCA). Thus a comprehensive monitoring framework is built. When the system enters a new operating condition, the RCA-RPCA model is rebuilt to deal with the new condition. Meanwhile, elastic weight consolidation (EWC) is employed to settle the `catastrophic forgetting' issue inherent in RPCA, where significant information of influential parameters is enhanced to avoid the abrupt performance degradation for similar modes. The effectiveness of the proposed method is illustrated by a practical industrial system.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge