Microstructure Surface Reconstruction from SEM Images: An Alternative to Digital Image Correlation (DIC)

Paper and Code

Mar 25, 2022

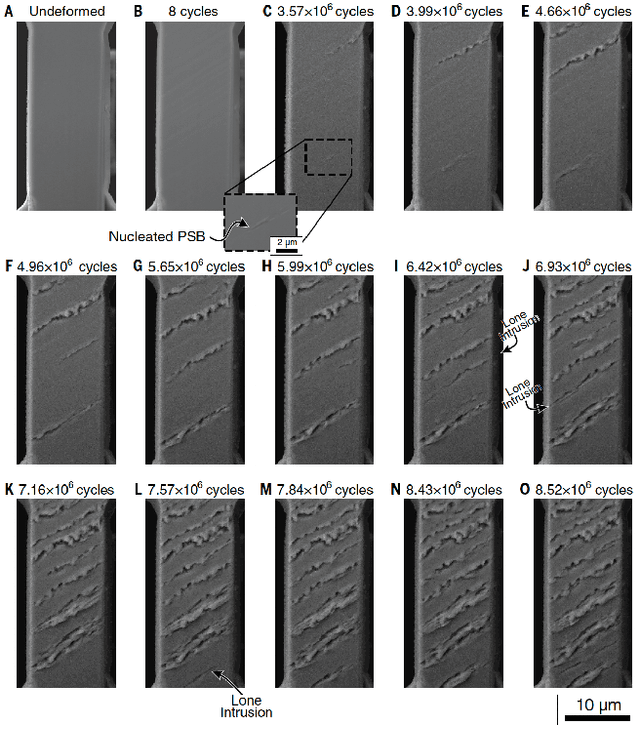

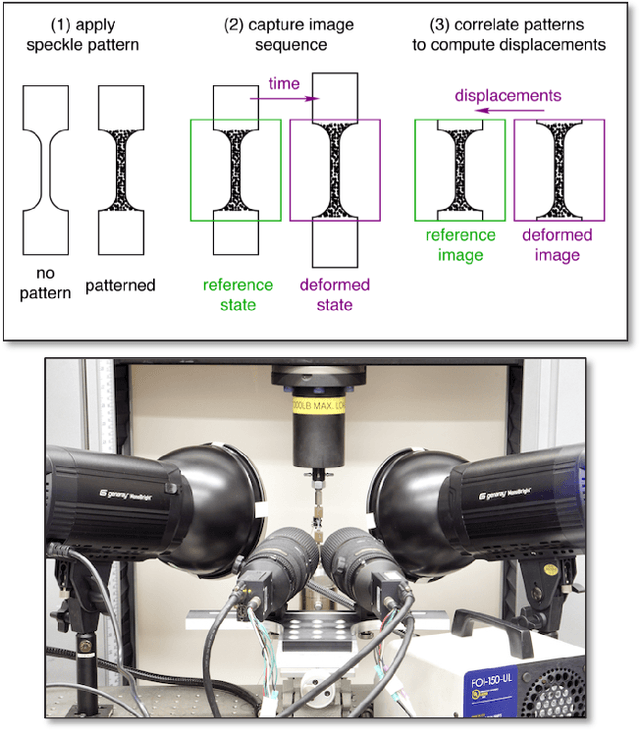

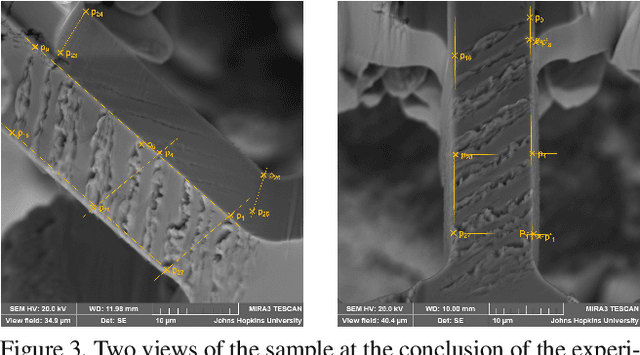

We reconstruct a 3D model of the surface of a material undergoing fatigue testing and experiencing cracking. Specifically we reconstruct the surface depth (out of plane intrusions and extrusions) and lateral (in-plane) motion from multiple views of the sample at the end of the experiment, combined with a reverse optical flow propagation backwards in time that utilizes interim single view images. These measurements can be mapped to a material strain tensor which helps to understand material life and predict failure. This approach offers an alternative to the commonly used Digital Image Correlation (DIC) technique which relies on tracking a speckle pattern applied to the material surface. DIC only produces in-plane (2D) measurements whereas our approach is 3D and non-invasive (requires no pattern being applied to the material).

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge