Machine Learning Approaches in Agile Manufacturing with Recycled Materials for Sustainability

Paper and Code

Mar 15, 2023

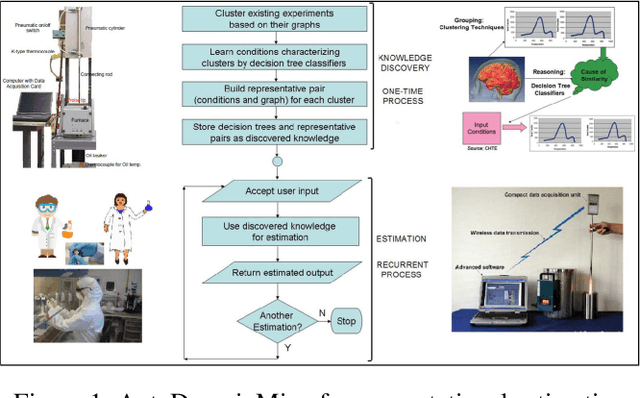

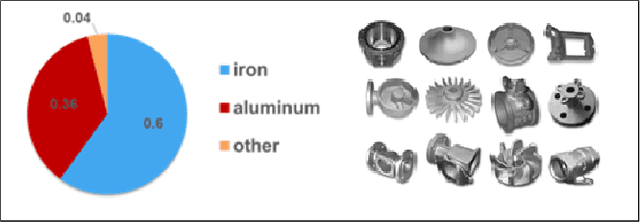

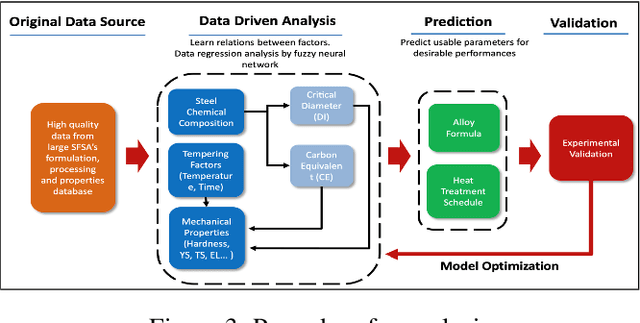

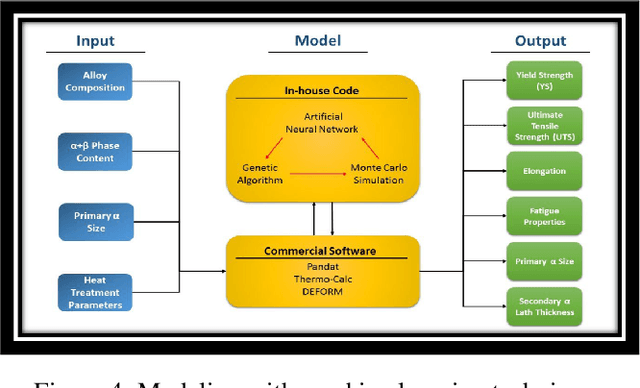

It is important to develop sustainable processes in materials science and manufacturing that are environmentally friendly. AI can play a significant role in decision support here as evident from our earlier research leading to tools developed using our proposed machine learning based approaches. Such tools served the purpose of computational estimation and expert systems. This research addresses environmental sustainability in materials science via decision support in agile manufacturing using recycled and reclaimed materials. It is a safe and responsible way to turn a specific waste stream to value-added products. We propose to use data-driven methods in AI by applying machine learning models for predictive analysis to guide decision support in manufacturing. This includes harnessing artificial neural networks to study parameters affecting heat treatment of materials and impacts on their properties; deep learning via advances such as convolutional neural networks to explore grain size detection; and other classifiers such as Random Forests to analyze phrase fraction detection. Results with all these methods seem promising to embark on further work, e.g. ANN yields accuracy around 90\% for predicting micro-structure development as per quench tempering, a heat treatment process. Future work entails several challenges: investigating various computer vision models (VGG, ResNet etc.) to find optimal accuracy, efficiency and robustness adequate for sustainable processes; creating domain-specific tools using machine learning for decision support in agile manufacturing; and assessing impacts on sustainability with metrics incorporating the appropriate use of recycled materials as well as the effectiveness of developed products. Our work makes impacts on green technology for smart manufacturing, and is motivated by related work in the highly interesting realm of AI for materials science.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge