Instance Segmentation of Industrial Point Cloud Data

Paper and Code

Dec 24, 2020

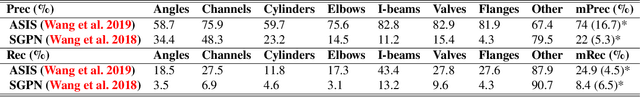

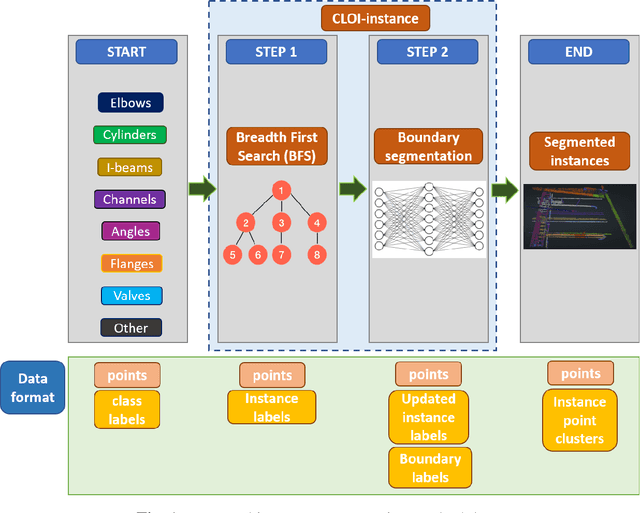

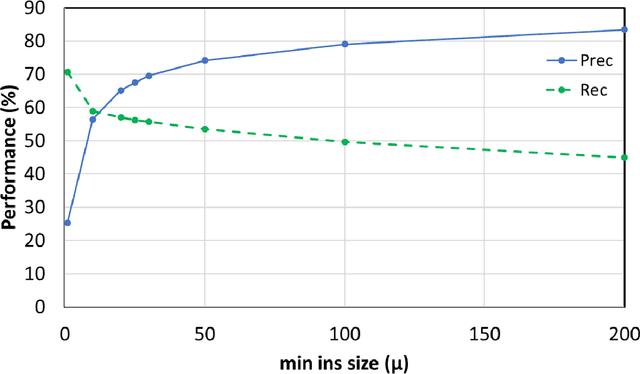

The challenge that this paper addresses is how to efficiently minimize the cost and manual labour for automatically generating object oriented geometric Digital Twins (gDTs) of industrial facilities, so that the benefits provide even more value compared to the initial investment to generate these models. Our previous work achieved the current state-of-the-art class segmentation performance (75% average accuracy per point and average AUC 90% in the CLOI dataset classes) as presented in (Agapaki and Brilakis 2020) and directly produces labelled point clusters of the most important to model objects (CLOI classes) from laser scanned industrial data. CLOI stands for C-shapes, L-shapes, O-shapes, I-shapes and their combinations. However, the problem of automated segmentation of individual instances that can then be used to fit geometric shapes remains unsolved. We argue that the use of instance segmentation algorithms has the theoretical potential to provide the output needed for the generation of gDTs. We solve instance segmentation in this paper through (a) using a CLOI-Instance graph connectivity algorithm that segments the point clusters of an object class into instances and (b) boundary segmentation of points that improves step (a). Our method was tested on the CLOI benchmark dataset (Agapaki et al. 2019) and segmented instances with 76.25% average precision and 70% average recall per point among all classes. This proved that it is the first to automatically segment industrial point cloud shapes with no prior knowledge other than the class point label and is the bedrock for efficient gDT generation in cluttered industrial point clouds.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge