How the Mechanical Properties and Thickness of Glass Affect TPaD Performance

Paper and Code

Dec 18, 2019

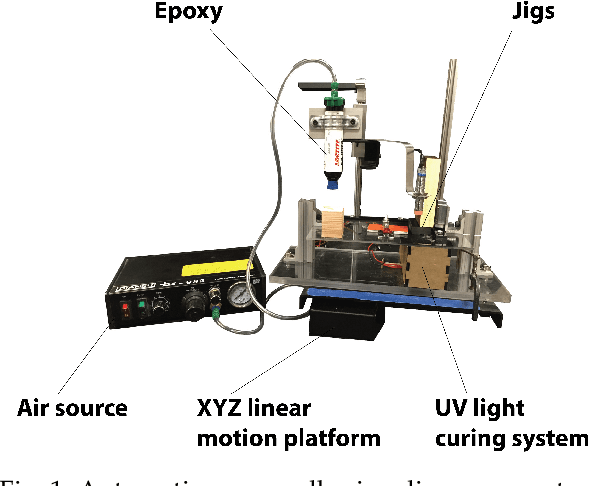

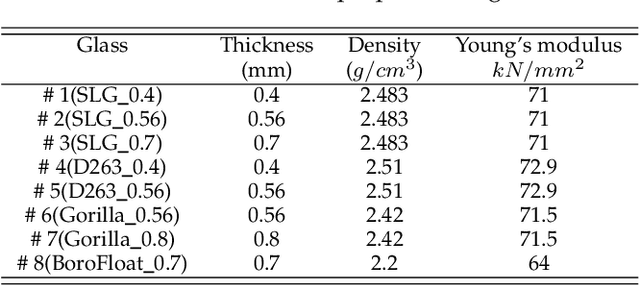

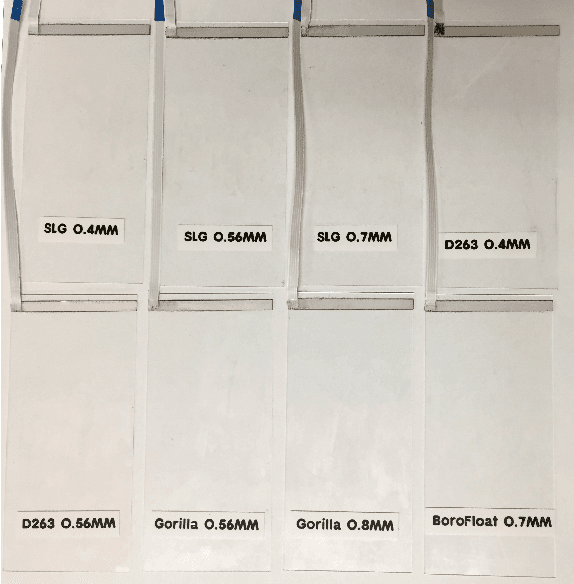

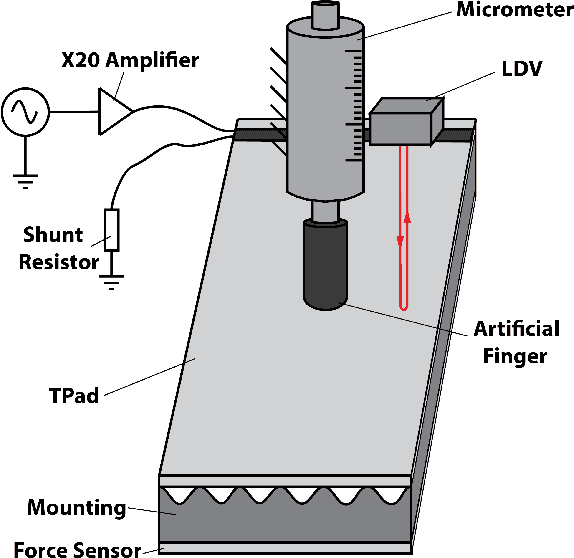

One well-known class of surface haptic devices that we have called TPaDs (Tactile Pattern Displays) uses ultrasonic transverse vibrations of a touch surface to modulate fingertip friction. This paper addresses the power consumption of glass TPaDs, which is an important consideration in the context of mobile touchscreens. In particular, based on existing ultrasonic friction reduction models, we consider how the mechanical properties (density and Young's modulus) and thickness of commonly-used glass formulations affect TPaD performance, namely the relation between friction reduction ability and real power consumption. Experiments performed with eight types of TPaDs and an electromechanical model for the fingertip-TPaD system indicate: 1) TPaD performance decreases as glass thickness increases; 2) TPaD performance increases as the Young's modulus and density of glass decrease; 3) counterintuitively, real power consumption of a TPaD decreases as the contact force increases. Proper applications of these results can lead to significant increases in TPaD performance.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge