How deals with discrete data for the reduction of simulation models using neural network

Paper and Code

Jun 10, 2009

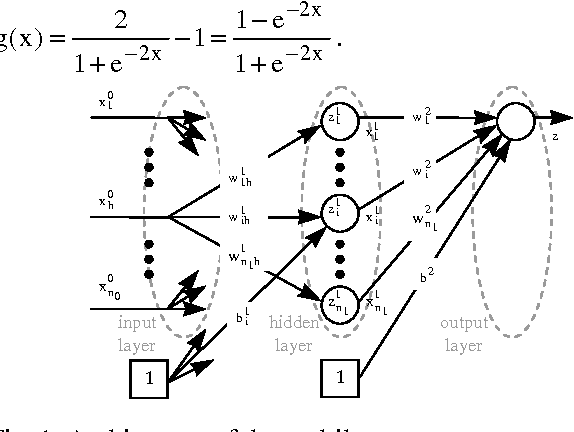

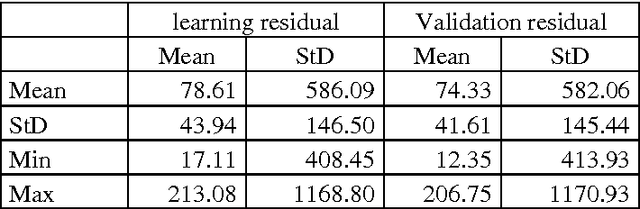

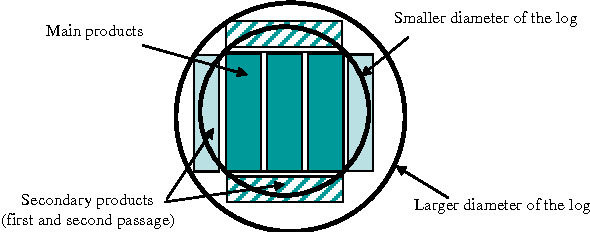

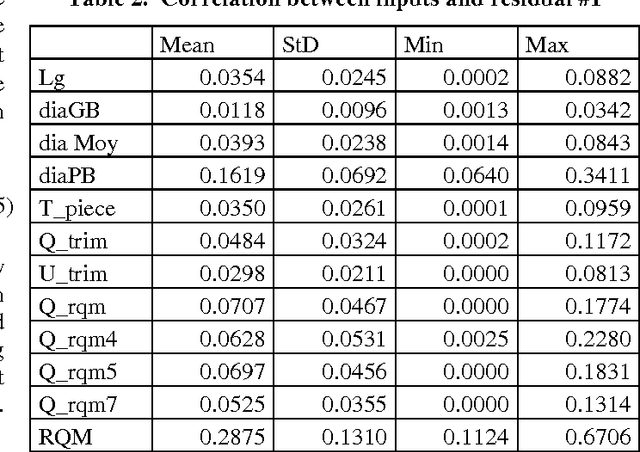

Simulation is useful for the evaluation of a Master Production/distribution Schedule (MPS). Also, the goal of this paper is the study of the design of a simulation model by reducing its complexity. According to theory of constraints, we want to build reduced models composed exclusively by bottlenecks and a neural network. Particularly a multilayer perceptron, is used. The structure of the network is determined by using a pruning procedure. This work focuses on the impact of discrete data on the results and compares different approaches to deal with these data. This approach is applied to sawmill internal supply chain

* 13th IFAC Symp. On Information Control Problems in Manufacturing

INCOM'09, Moscou : Russie (2009)

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge