Holistic Fault Detection and Diagnosis System in Imbalanced, Scarce, Multi-Domain (ISMD) Data Setting for Component-Level Prognostics and Health Management (PHM)

Paper and Code

Mar 18, 2022

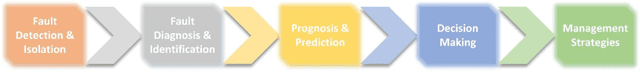

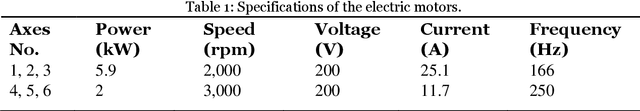

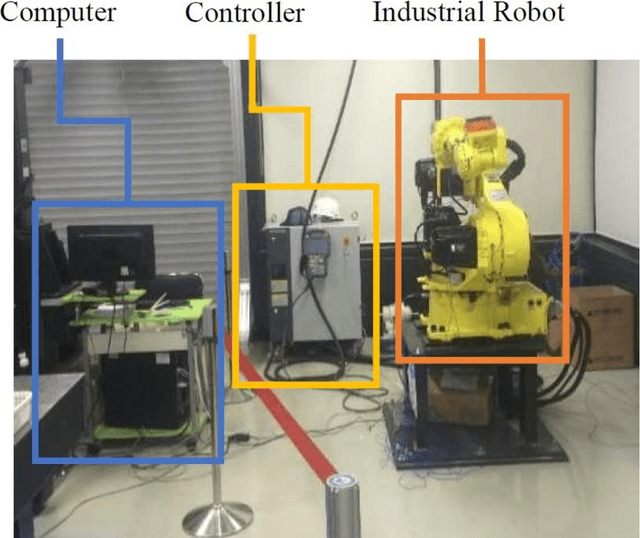

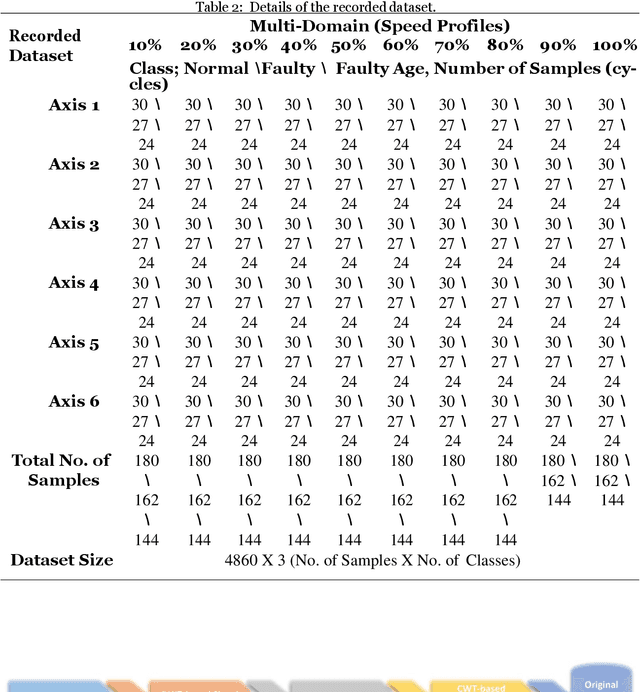

In the current Industrial 4.0 revolution, Prognostics and Health Management (PHM) is an emerging field of research. The difficulty of obtaining data from electromechanical systems in an industrial setting increases proportionally with the scale and accessibility of the automated industry, resulting in a less interpolated PHM system. To put it another way, the development of an accurate PHM system for each industrial system necessitates a unique dataset acquired under specified conditions. In most circumstances, obtaining this one-of-a-kind dataset is difficult, and the resulting dataset has a significant imbalance, a lack of certain useful information, and multi-domain knowledge. To address this, this paper provides a fault detection and diagnosis system that evaluates and pre-processes Imbalanced, Scarce, Multi-Domain (ISMD) data acquired from an industrial robot utilizing Signal Processing (SP) techniques and Deep Learning-based (DL) domain knowledge transfer. The domain knowledge transfer is used to produce a synthetic dataset with a high interpolation rate that contains all the useful information about each domain. For domain knowledge transfer and data generation, Continuous Wavelet Transform (CWT) with Generative Adversarial Network (GAN) was used, as well as Convolutional Neural Network (CNN) to test the suggested methodology using transfer learning and categorize several faults. The proposed methodology was tested on a real experimental bench that included an industrial robot created by Hyundai Robotics Co. This development resulted in a satisfactory resolution with 99.7% (highest) classification accuracy achieved by transfer learning on several CNN benchmark models.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge