Feature Analyses and Modelling of Lithium-ion Batteries Manufacturing based on Random Forest Classification

Paper and Code

Feb 10, 2021

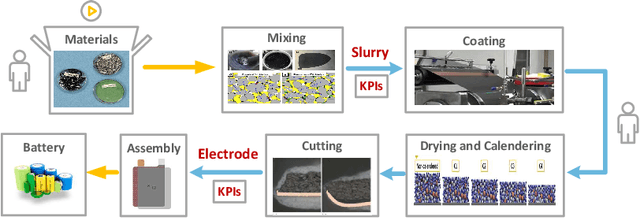

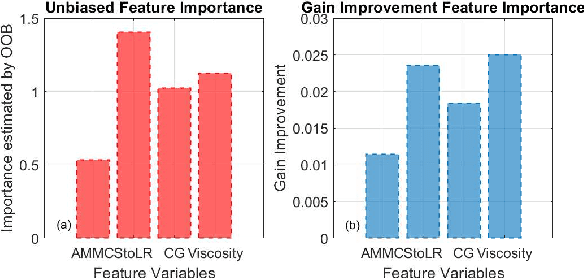

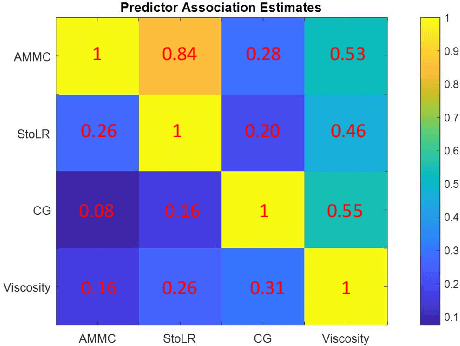

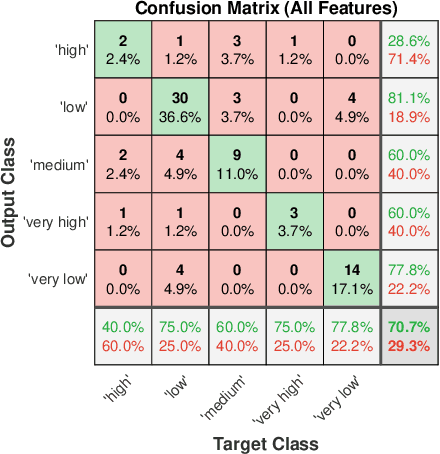

Lithium-ion battery manufacturing is a highly complicated process with strongly coupled feature interdependencies, a feasible solution that can analyse feature variables within manufacturing chain and achieve reliable classification is thus urgently needed. This article proposes a random forest (RF)-based classification framework, through using the out of bag (OOB) predictions, Gini changes as well as predictive measure of association (PMOA), for effectively quantifying the importance and correlations of battery manufacturing features and their effects on the classification of electrode properties. Battery manufacturing data containing three intermediate product features from the mixing stage and one product parameter from the coating stage are analysed by the designed RF framework to investigate their effects on both the battery electrode active material mass load and porosity. Illustrative results demonstrate that the proposed RF framework not only achieves the reliable classification of electrode properties but also leads to the effective quantification of both manufacturing feature importance and correlations. This is the first time to design a systematic RF framework for simultaneously quantifying battery production feature importance and correlations by three various quantitative indicators including the unbiased feature importance (FI), gain improvement FI and PMOA, paving a promising solution to reduce model dimension and conduct efficient sensitivity analysis of battery manufacturing.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge