Design, Fabrication and Control of an Hydraulic Elastomer Actuator

Paper and Code

Jun 13, 2018

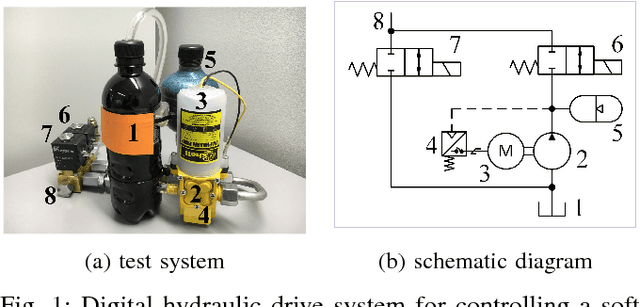

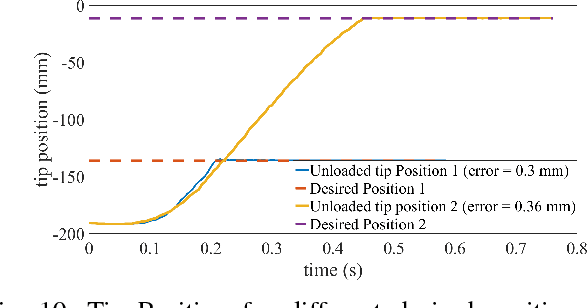

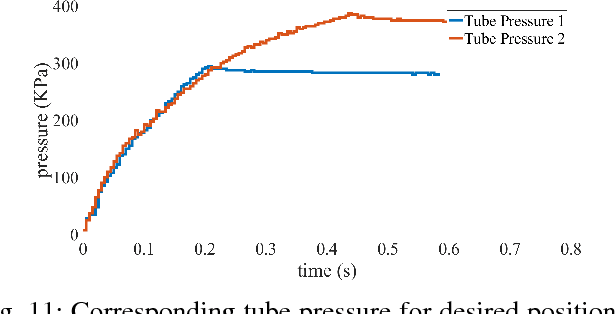

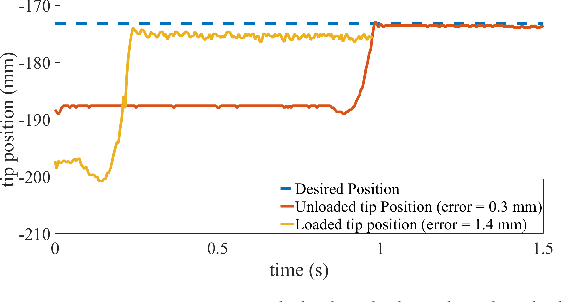

This paper presents design, fabrication and control of a compliant 2D manipulator, a so called soft actuator. Our focus is on fiber-reinforced elastomer actuators driven by a constant pressure hydraulic supply and modulated on/off valves. For a given diameters, we study the effect of four different elastomer materials and that of number of reinforcement fiber turns on forces generated by the actuator and maximum bending angles. For the rest of the study, we use polydimethylosiloxane (PDMS) with 240 fiber turns per 170mm length of actuator which withstand highest pressures and forces in our experiments. For the rest of the paper, we introduce two control methodologies. Firstly, we show that is possible to reasonably accurately control the pressure inside tube without measuring the pressure incorporating a simple linear tube model. This can be used, for example, in an inner-outer loop configuration with a PI position control to achieve high performance without the need for pressure measurement. Secondly, we experimentally show that a switching position control exhibits very good steady state accuracy and acceptable transient. Actuator tip position is measured using an external vision system. Our experiments included performance analysis of our soft manipulator while freely moving as well as when carrying a load.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge