Computer Vision and Normalizing Flow Based Defect Detection

Paper and Code

Dec 12, 2020

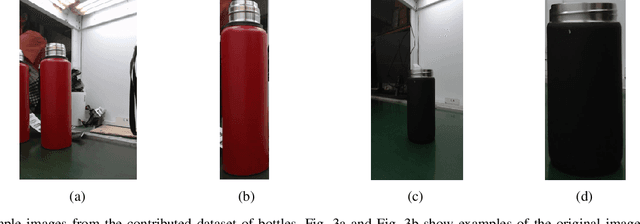

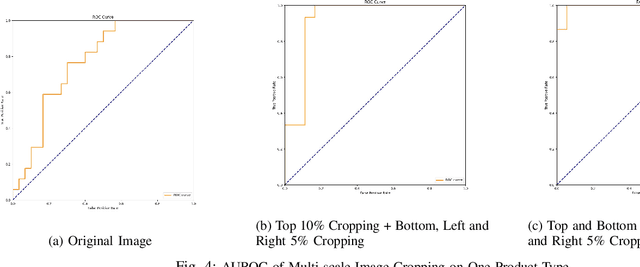

Surface defect detection is essential and necessary for controlling the qualities of the products during manufacturing. The challenges in this complex task include: 1) collecting defective samples and manually labeling for training is time-consuming; 2) the defects' characteristics are difficult to define as new types of defect can happen all the time; 3) and the real-world product images contain lots of background noise. In this paper, we present a two-stage defect detection network based on the object detection model YOLO, and the normalizing flow-based defect detection model DifferNet. Our model has high robustness and performance on defect detection using real-world video clips taken from a production line monitoring system. The normalizing flow-based anomaly detection model only requires a small number of good samples for training and then perform defect detection on the product images detected by YOLO. The model we invent employs two novel strategies: 1) a two-stage network using YOLO and a normalizing flow-based model to perform product defect detection, 2) multi-scale image transformations are implemented to solve the issue product image cropped by YOLO includes many background noise. Besides, extensive experiments are conducted on a new dataset collected from the real-world factory production line. We demonstrate that our proposed model can learn on a small number of defect-free samples of single or multiple product types. The dataset will also be made public to encourage further studies and research in surface defect detection.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge