Breaking Moravec's Paradox: Visual-Based Distribution in Smart Fashion Retail

Paper and Code

Jul 10, 2020

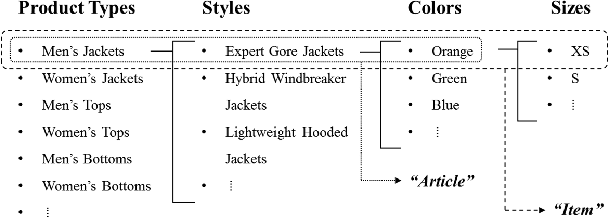

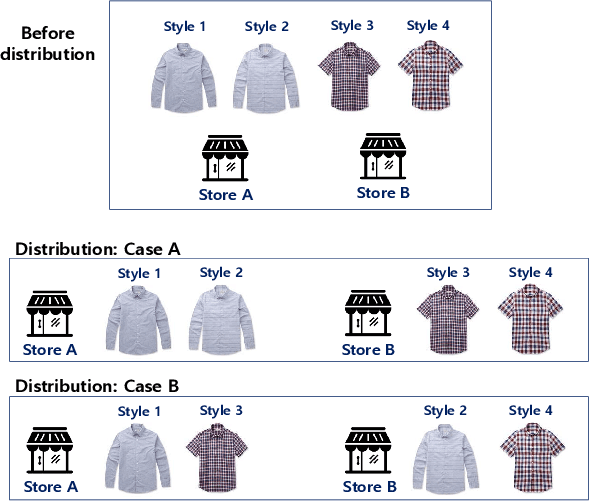

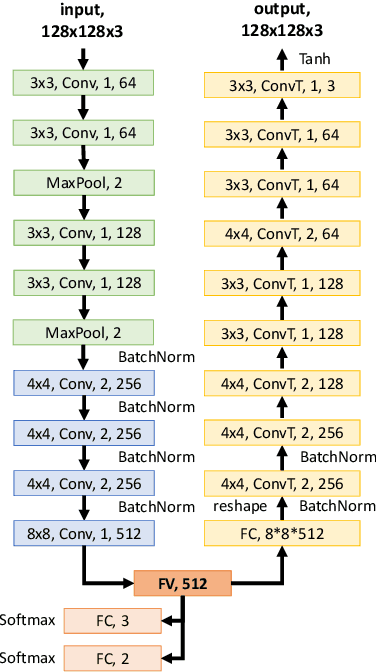

In this paper, we report an industry-academia collaborative study on the distribution method of fashion products using an artificial intelligence (AI) technique combined with an optimization method. To meet the current fashion trend of short product lifetimes and an increasing variety of styles, the company produces limited volumes of a large variety of styles. However, due to the limited volume of each style, some styles may not be distributed to some off-line stores. As a result, this high-variety, low-volume strategy presents another challenge to distribution managers. We collaborated with KOLON F/C, one of the largest fashion business units in South Korea, to develop models and an algorithm to optimally distribute the products to the stores based on the visual images of the products. The team developed a deep learning model that effectively represents the styles of clothes based on their visual image. Moreover, the team created an optimization model that effectively determines the product mix for each store based on the image representation of clothes. In the past, computers were only considered to be useful for conducting logical calculations, and visual perception and cognition were considered to be difficult computational tasks. The proposed approach is significant in that it uses both AI (perception and cognition) and mathematical optimization (logical calculation) to address a practical supply chain problem, which is why the study was called "Breaking Moravec's Paradox."

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge