Automatic Defect Detection in Sewer Network Using Deep Learning Based Object Detector

Paper and Code

Apr 09, 2024

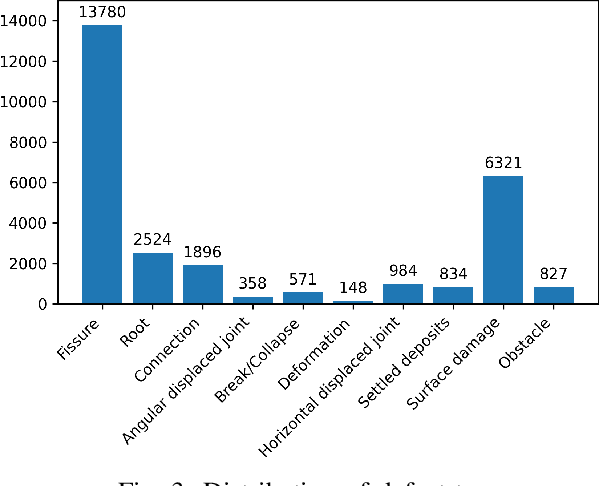

Maintaining sewer systems in large cities is important, but also time and effort consuming, because visual inspections are currently done manually. To reduce the amount of aforementioned manual work, defects within sewer pipes should be located and classified automatically. In the past, multiple works have attempted solving this problem using classical image processing, machine learning, or a combination of those. However, each provided solution only focus on detecting a limited set of defect/structure types, such as fissure, root, and/or connection. Furthermore, due to the use of hand-crafted features and small training datasets, generalization is also problematic. In order to overcome these deficits, a sizable dataset with 14.7 km of various sewer pipes were annotated by sewer maintenance experts in the scope of this work. On top of that, an object detector (EfficientDet-D0) was trained for automatic defect detection. From the result of several expermients, peculiar natures of defects in the context of object detection, which greatly effect annotation and training process, are found and discussed. At the end, the final detector was able to detect 83% of defects in the test set; out of the missing 17%, only 0.77% are very severe defects. This work provides an example of applying deep learning-based object detection into an important but quiet engineering field. It also gives some practical pointers on how to annotate peculiar "object", such as defects.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge