Auto-encoder based Model for High-dimensional Imbalanced Industrial Data

Paper and Code

Aug 05, 2021

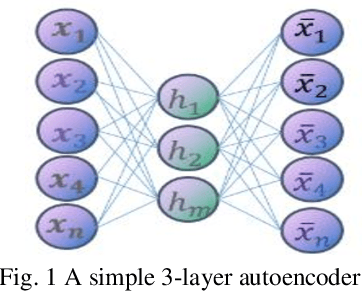

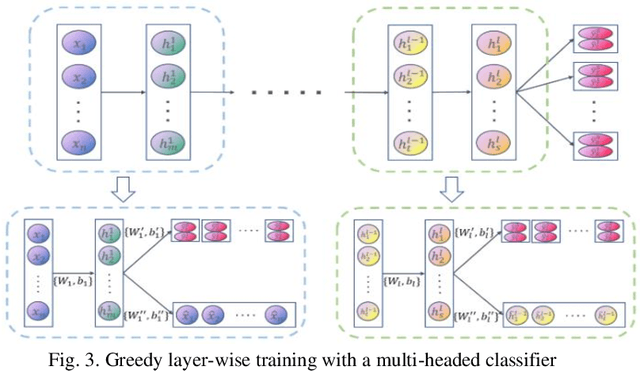

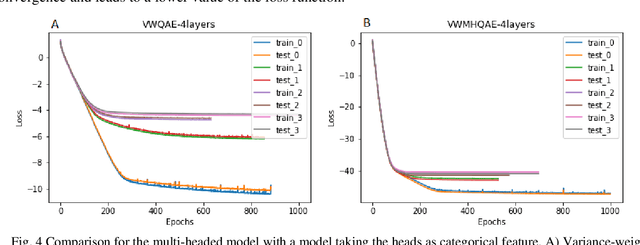

With the proliferation of IoT devices, the distributed control systems are now capturing and processing more sensors at higher frequency than ever before. These new data, due to their volume and novelty, cannot be effectively consumed without the help of data-driven techniques. Deep learning is emerging as a promising technique to analyze these data, particularly in soft sensor modeling. The strong representational capabilities of complex data and the flexibility it offers from an architectural perspective make it a topic of active applied research in industrial settings. However, the successful applications of deep learning in soft sensing are still not widely integrated in factory control systems, because most of the research on soft sensing do not have access to large scale industrial data which are varied, noisy and incomplete. The results published in most research papers are therefore not easily reproduced when applied to the variety of data in industrial settings. Here we provide manufacturing data sets that are much larger and more complex than public open soft sensor data. Moreover, the data sets are from Seagate factories on active service with only necessary anonymization, so that they reflect the complex and noisy nature of real-world data. We introduce a variance weighted multi-headed auto-encoder classification model that fits well into the high-dimensional and highly imbalanced data. Besides the use of weighting or sampling methods to handle the highly imbalanced data, the model also simultaneously predicts multiple outputs by exploiting output-supervised representation learning and multi-task weighting.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge