An Ontology for Defect Detection in Metal Additive Manufacturing

Paper and Code

Sep 29, 2022

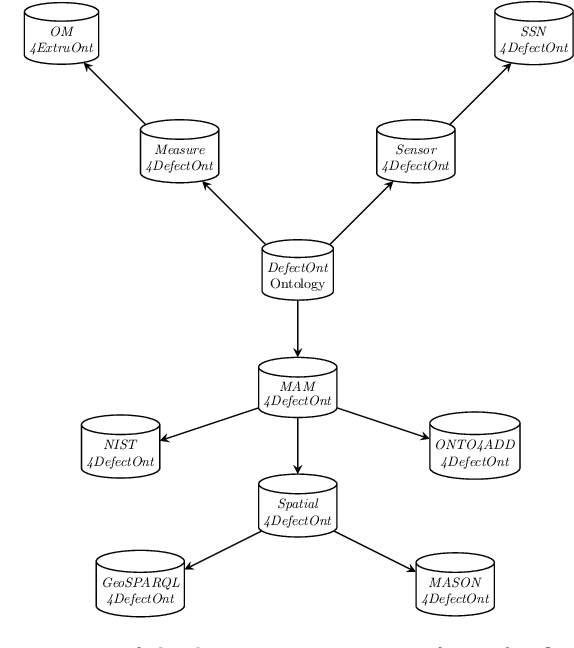

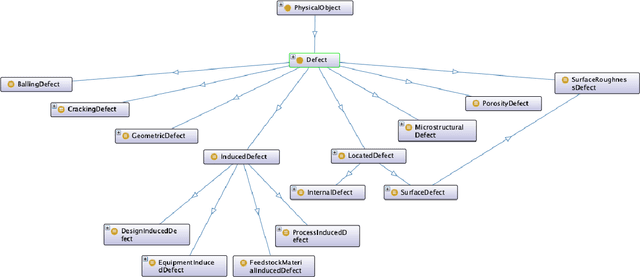

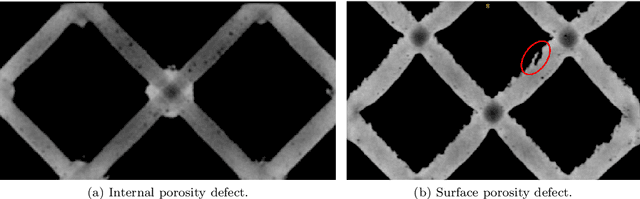

A key challenge for Industry 4.0 applications is to develop control systems for automated manufacturing services that are capable of addressing both data integration and semantic interoperability issues, as well as monitoring and decision making tasks. To address such an issue in advanced manufacturing systems, principled knowledge representation approaches based on formal ontologies have been proposed as a foundation to information management and maintenance in presence of heterogeneous data sources. In addition, ontologies provide reasoning and querying capabilities to aid domain experts and end users in the context of constraint validation and decision making. Finally, ontology-based approaches to advanced manufacturing services can support the explainability and interpretability of the behaviour of monitoring, control, and simulation systems that are based on black-box machine learning algorithms. In this work, we provide a novel ontology for the classification of process-induced defects known from the metal additive manufacturing literature. Together with a formal representation of the characterising features and sources of defects, we integrate our knowledge base with state-of-the-art ontologies in the field. Our knowledge base aims at enhancing the modelling capabilities of additive manufacturing ontologies by adding further defect analysis terminology and diagnostic inference features.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge