An image-driven machine learning approach to kinetic modeling of a discontinuous precipitation reaction

Paper and Code

Jun 13, 2019

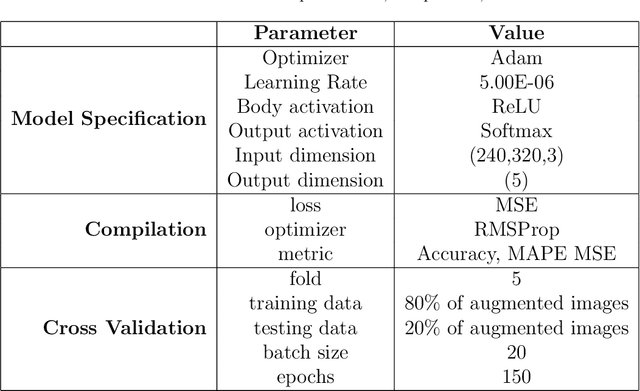

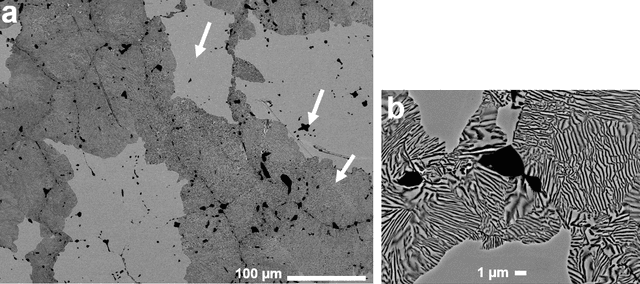

Micrograph quantification is an essential component of several materials science studies. Machine learning methods, in particular convolutional neural networks, have previously demonstrated performance in image recognition tasks across several disciplines (e.g. materials science, medical imaging, facial recognition). Here, we apply these well-established methods to develop an approach to microstructure quantification for kinetic modeling of a discontinuous precipitation reaction in a case study on the uranium-molybdenum system. Prediction of material processing history based on image data (classification), calculation of area fraction of phases present in the micrographs (segmentation), and kinetic modeling from segmentation results were performed. Results indicate that convolutional neural networks represent microstructure image data well, and segmentation using the k-means clustering algorithm yields results that agree well with manually annotated images. Classification accuracies of original and segmented images are both 94\% for a 5-class classification problem. Kinetic modeling results agree well with previously reported data using manual thresholding. The image quantification and kinetic modeling approach developed and presented here aims to reduce researcher bias introduced into the characterization process, and allows for leveraging information in limited image data sets.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge