An Evaluation of Classification Methods for 3D Printing Time-Series Data

Paper and Code

Oct 02, 2020

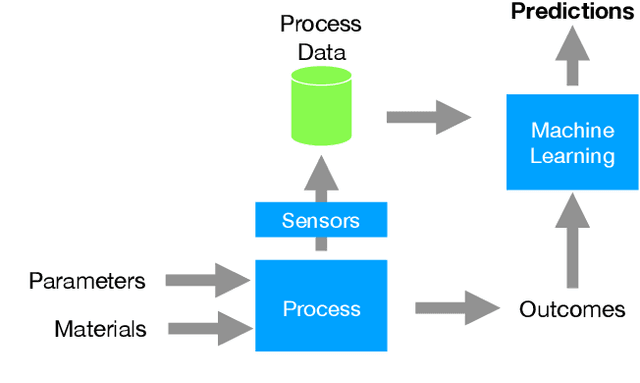

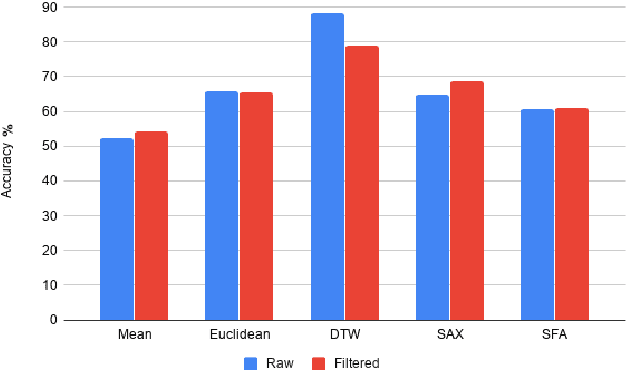

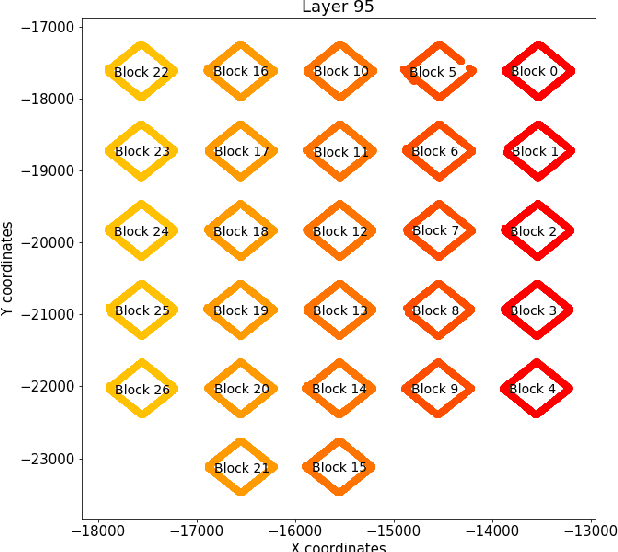

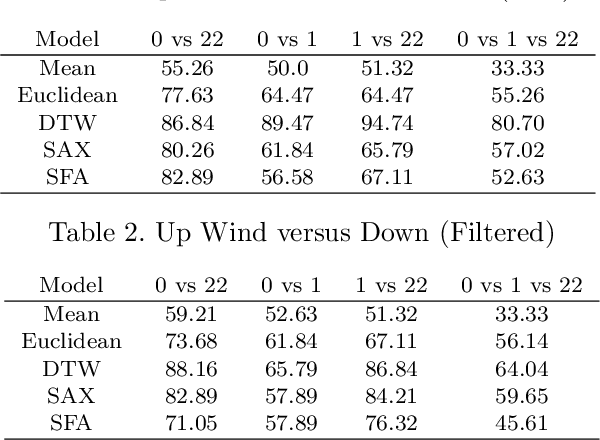

Additive Manufacturing presents a great application area for Machine Learning because of the vast volume of data generated and the potential to mine this data to control outcomes. In this paper we present preliminary work on classifying infrared time-series data representing melt-pool temperature in a metal 3D printing process. Our ultimate objective is to use this data to predict process outcomes (e.g. hardness, porosity, surface roughness). In the work presented here we simply show that there is a signal in this data that can be used for the classification of different components and stages of the AM process. In line with other Machine Learning research on time-series classification we use k-Nearest Neighbour classifiers. The results we present suggests that Dynamic Time Warping is an effective distance measure compared with alternatives for 3D printing data of this type.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge