An Automated System for Detecting Visual Damages of Wind Turbine Blades

Paper and Code

May 22, 2022

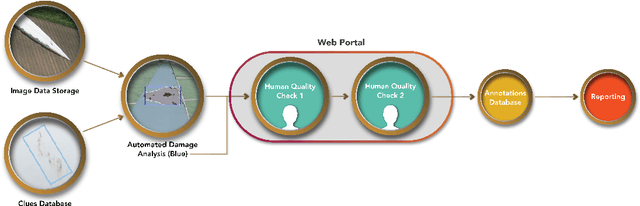

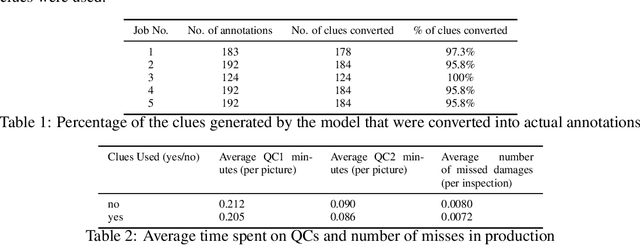

Wind energy's ability to compete with fossil fuels on a market level depends on lowering wind's high operational costs. Since damages on wind turbine blades are the leading cause for these operational problems, identifying blade damages is critical. However, recent works in visual identification of blade damages are still experimental and focus on optimizing the traditional machine learning metrics such as IoU. In this paper, we argue that pushing models to production long before achieving the "optimal" model performance can still generate real value for this use case. We discuss the performance of our damage's suggestion model in production and how this system works in coordination with humans as part of a commercialized product and how it can contribute towards lowering wind energy's operational costs.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge