A Physics-Informed Machine Learning Approach for Solving Heat Transfer Equation in Advanced Manufacturing and Engineering Applications

Paper and Code

Sep 28, 2020

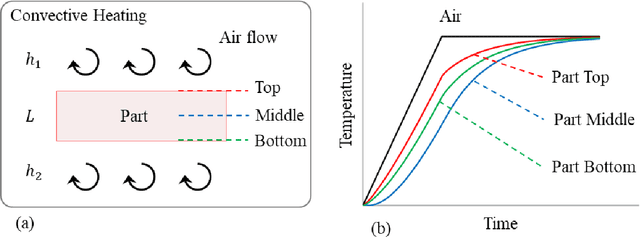

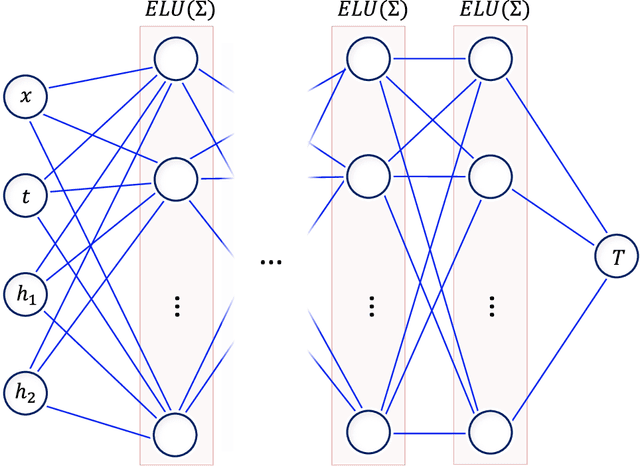

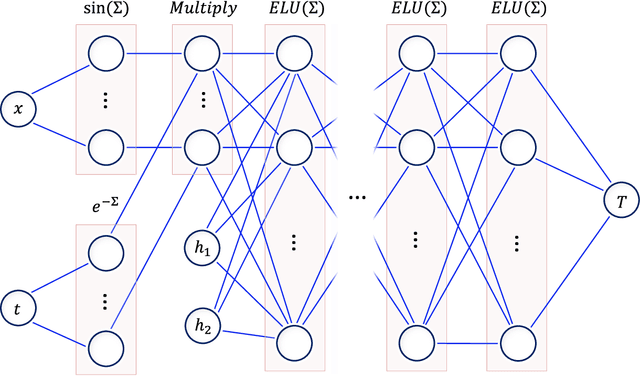

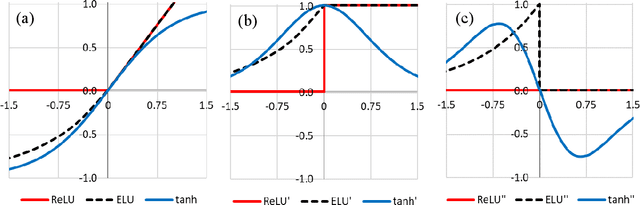

A physics-informed neural network is developed to solve conductive heat transfer partial differential equation (PDE), along with convective heat transfer PDEs as boundary conditions (BCs), in manufacturing and engineering applications where parts are heated in ovens. Since convective coefficients are typically unknown, current analysis approaches based on trial and error finite element (FE) simulations are slow. The loss function is defined based on errors to satisfy PDE, BCs and initial condition. An adaptive normalizing scheme is developed to reduce loss terms simultaneously. In addition, theory of heat transfer is used for feature engineering. The predictions for 1D and 2D cases are validated by comparing with FE results. It is shown that using engineered features, heat transfer beyond the training zone can be predicted. Trained model allows for fast evaluation of a range of BCs to develop feedback loops, realizing Industry 4.0 concept of active manufacturing control based on sensor data.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge