A Machine Learning Framework for Real-time Inverse Modeling and Multi-objective Process Optimization of Composites for Active Manufacturing Control

Paper and Code

Apr 22, 2021

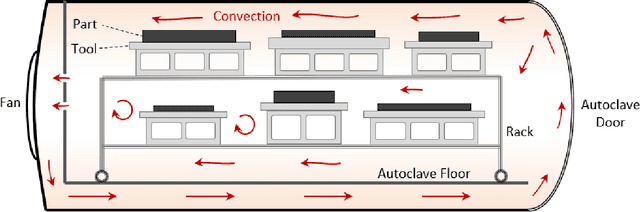

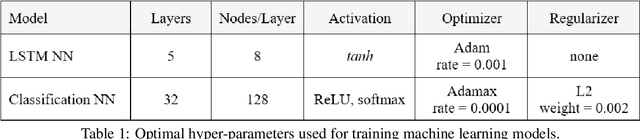

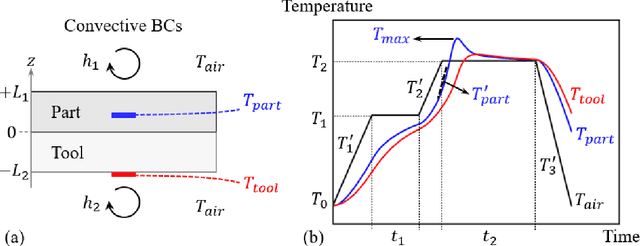

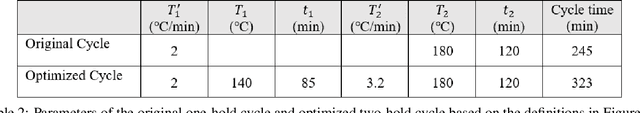

For manufacturing of aerospace composites, several parts may be processed simultaneously using convective heating in an autoclave. Due to uncertainties including tool placement, convective Boundary Conditions (BCs) vary in each run. As a result, temperature histories in some of the parts may not conform to process specifications due to under-curing or over-heating. Thermochemical analysis using Finite Element (FE) simulations are typically conducted prior to fabrication based on assumed range of BCs. This, however, introduces unnecessary constraints on the design. To monitor the process, thermocouples (TCs) are placed under tools near critical locations. The TC data may be used to back-calculate BCs using trial-and-error FE analysis. However, since the inverse heat transfer problem is ill-posed, many solutions are obtained for given TC data. In this study, a novel machine learning (ML) framework is presented capable of optimizing air temperature cycle in real-time based on TC data from multiple parts, for active control of manufacturing. The framework consists of two recurrent Neural Networks (NN) for inverse modeling of the ill-posed curing problem at the speed of 300 simulations/second, and a classification NN for multi-objective optimization of the air temperature at the speed of 35,000 simulations/second. A virtual demonstration of the framework for process optimization of three composite parts with data from three TCs is presented.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge