A Compact Optical Six-Axis Force/Torque Sensor for Legged Robots Using a Polymorphic Calibration Method

Paper and Code

Sep 20, 2023

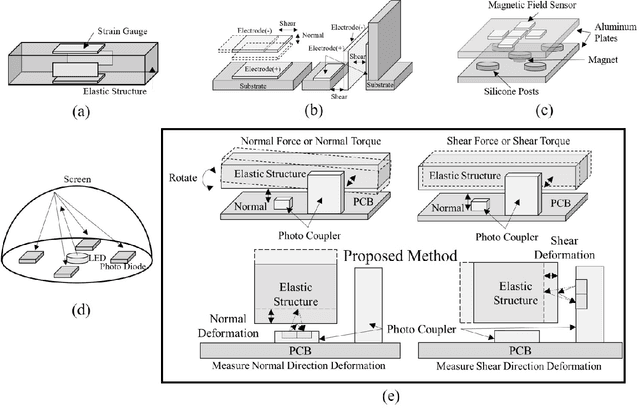

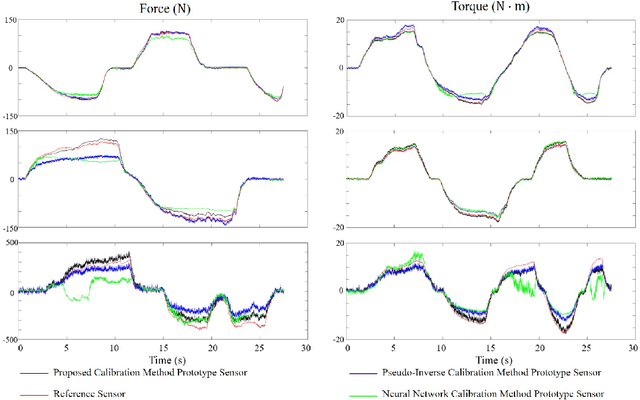

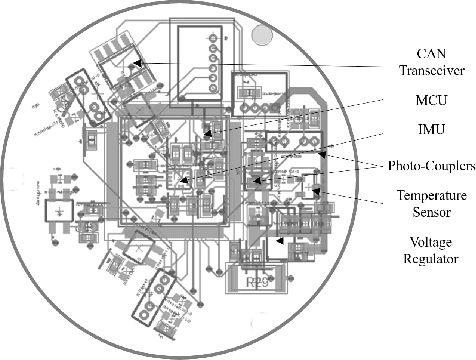

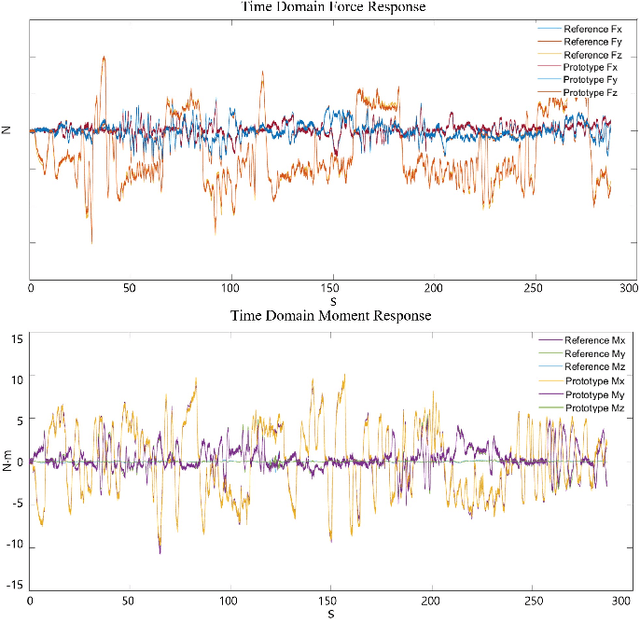

This paper presents a novel design for a compact, lightweight 6-axis force/torque sensor intended for use in legged robots. The design promotes easy manufacturing and cost reduction, while introducing innovative calibration methods that simplify the calibration process and minimize effort. The sensor's advantages are achieved by streamlining the structure for durability, implementing noncontact sensors, and providing a wider sensing range compared to commercial sensors. To maintain a simple structure, the paper proposes a force sensing scheme using photocouplers where the sensing elements are aligned in-plane. This strategy enables all sensing elements to be fabricated on a single printed circuit board, eliminating manual labor tasks such as bonding and coating the sensing elements. The prototype sensor contains only four parts, costs less than $250, and exhibits high response frequency and performance. Traditional calibration methods present challenges, such as the need for specialized equipment and extensive labor. To facilitate easy calibration without the need for specialized equipment, a new method using optimal control is proposed. To verify the feasibility of these ideas, a prototype six-axis F/T sensor was manufactured. Its performance was evaluated and compared to a reference F/T sensor and previous calibration methods.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge