Peter M. Attia

A dataset of over one thousand computed tomography scans of battery cells

Mar 12, 2024

Abstract:Battery technology is increasingly important for global electrification efforts. However, batteries are highly sensitive to small manufacturing variations that can induce reliability or safety issues. An important technology for battery quality control is computed tomography (CT) scanning, which is widely used for non-destructive 3D inspection across a variety of clinical and industrial applications. Historically, however, the utility of CT scanning for high-volume manufacturing has been limited by its low throughput as well as the difficulty of handling its large file sizes. In this work, we present a dataset of over one thousand CT scans of as-produced commercially available batteries. The dataset spans various chemistries (lithium-ion and sodium-ion) as well as various battery form factors (cylindrical, pouch, and prismatic). We evaluate seven different battery types in total. The manufacturing variability and the presence of battery defects can be observed via this dataset. This dataset may be of interest to scientists and engineers working on battery technology, computer vision, or both.

Predicting the impact of formation protocols on battery lifetime immediately after manufacturing

Mar 26, 2022

Abstract:Increasing the speed of battery formation can significantly lower lithium-ion battery manufacturing costs. However, adopting faster formation protocols in practical manufacturing settings is challenging due to a lack of inexpensive, rapid diagnostic signals that can inform possible impacts to long-term battery lifetime. This work identifies the cell resistance measured at low states of charge as an early-life diagnostic feature for screening new formation protocols. We show that this signal correlates to cycle life and improves the accuracy of data-driven battery lifetime prediction models. The signal is obtainable at the end of the manufacturing line, takes seconds to acquire, and does not require specialized test equipment. We explore a physical connection between this resistance signal and the quantity of lithium consumed during formation, suggesting that the signal may be broadly applicable for evaluating any manufacturing process change that could impact the total lithium consumed during formation.

Statistical learning for accurate and interpretable battery lifetime prediction

Jan 06, 2021

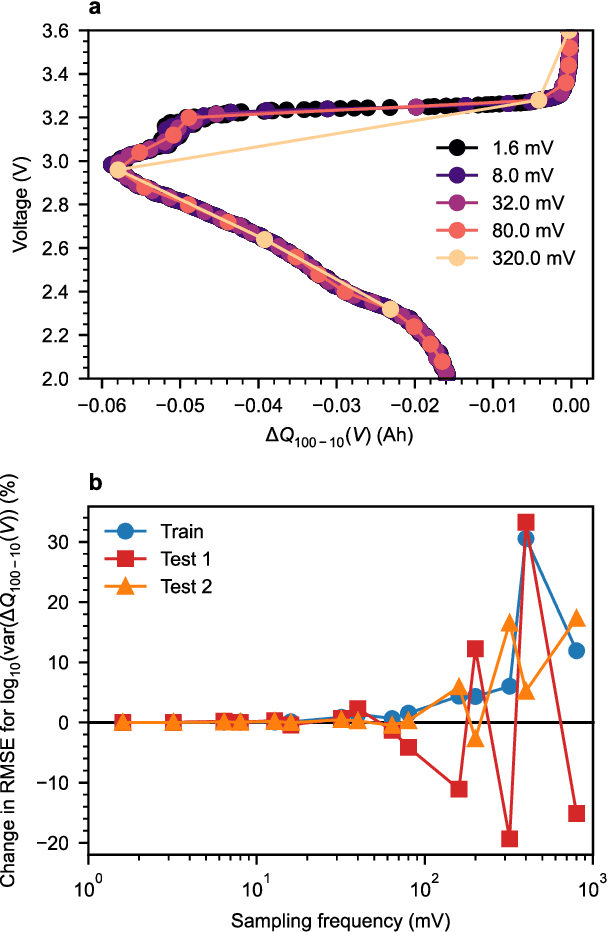

Abstract:Data-driven methods for battery lifetime prediction are attracting increasing attention for applications in which the degradation mechanisms are poorly understood and suitable training sets are available. However, while advanced machine learning and deep learning methods offer high performance with minimal feature engineering, simpler "statistical learning" methods often achieve comparable performance, especially for small training sets, while also providing physical and statistical interpretability. In this work, we use a previously published dataset to develop simple, accurate, and interpretable data-driven models for battery lifetime prediction. We first present the "capacity matrix" concept as a compact representation of battery electrochemical cycling data, along with a series of feature representations. We then create a number of univariate and multivariate models, many of which achieve comparable performance to the highest-performing models previously published for this dataset. These models also provide insights into the degradation of these cells. Our approaches can be used both to quickly train models for a new dataset and to benchmark the performance of more advanced machine learning methods.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge